Mini Truckin

Hey kids, wanna drive your own rig? Check this out!

Have you guys seen this cool mini rig on social media yet? Owned by Heikell Transport in Whakatane, the mini ride-on Scania is made by a company in Ireland called Scaled Rigs, and Heikell’s added it to its ‘fleet’ in 2020.

Then, early this year, stock- crates builder Nationwide Stock Crates from Mount Maunganui (which builds all the crates for Heikell’s fleet of stock trucks) handed over the custom tri-axle semi-trailer, completing the rig. Nationwide made sure the trailer is all kid-friendly, ensuring there are no sharp edges or surfaces that could cause harm – just like it does for the real crates that cart animals.

Both the truck tractor and trailer are done in full Heikell Transport livery. The awesome graphics on the side of the mini-Scania are a replica of that on fleet No.16, a Scania S650 8×4 known as ‘Legend II’.

There’s even working lights behind the cab and on the trailer – just like the real thing! It has real pneumatic tyres (meaning they’re filled with air), is battery powered and has forward and reverse gears. It’ll do a top speed of 6kph, more than enough to have some good fun. And, when you put your foot down, the truck makes a realistic sounding engine noise.

Now that’s a cool toy!

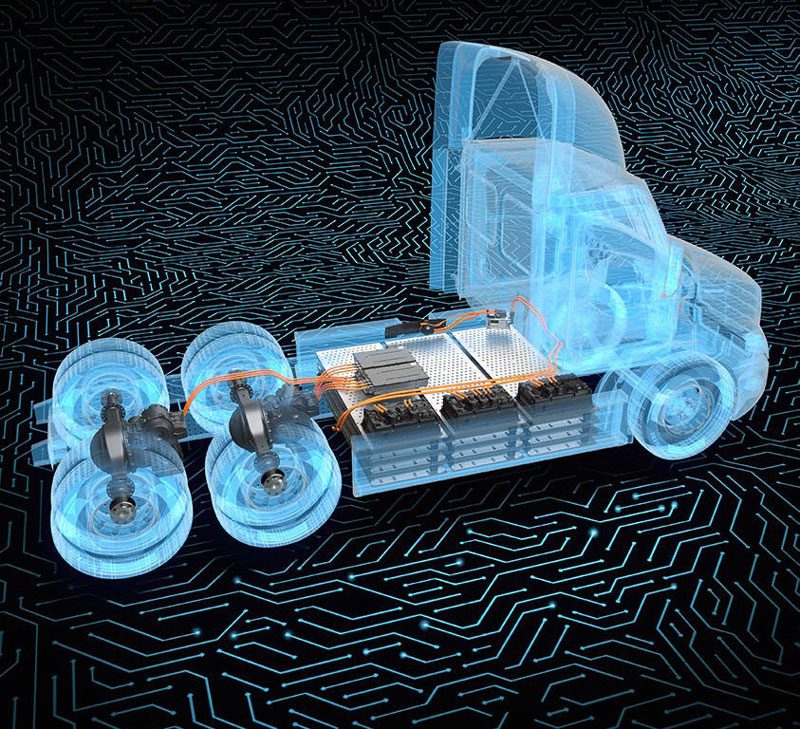

Everything you need to know about Electric Trucks

What is an electric vehicle? Why are they a good option? Are they the future?

What is an electric vehicle/truck?

The electric automobile is a motor vehicle powered by rechargeable batteries rather than fossil fuels. Petrol and diesel are fossil fuels.

Why electric trucks?

Electric vehicles are more energy efficient and have a lower environmental impact. The environmental impact of an electric truck is very low when the truck is in use, in fact they produce zero emissions on the road and are very very very quiet. They are so quiet, manufacturers have to add sounds to the vehicles to ensure pedestrians and cyclists can hear them. EVs are energy efficient. They convert more than 77% of the electrical energy from the grid to power at the wheels. Conventional diesel or petrol vehicles only convert about 12%–30% of the energy stored in fossil fuel to power at the wheels.

Electric Trucks Down Under:

The eCanter, an electric truck from FUSO, is the world’s first series-produced, fully electric light truck that is available in the New Zealand market. It is ideal for inner-city deliveries.

There are many manufacturers developing and road-testing battery- electric, heavy-duty electric trucks such as the eActros from Mercedes-Benz and eCascadia from Freightliner, so expect to see more electric trucks on Australian and New Zealand roads in the not-to- distanced future!

Restoring a classic truck Part 1

1997 Kenworth W924 – A labour of love with Graeme Skou.

We all enjoy seeing trucks on the road and at shows that make us go WOW!

Have you ever wondered how they get them looking so flash? How much work goes into them? How are they put together? I may be able to answer some of your questions!

I met Graeme Skou and he has shared two of his rebuild stories with us. Today we will look at his 1977 Kenworth W924.

Graeme has always been a Mack man at heart, but he chose to rebuild a Kenworth W924 because they look good and have strong bones. He bought the truck in 2016 and it took him five years to restore. It was never his plan to take that long, but due to the truck previously living near the ocean there was quite a bit of corrosion/rust that needed to be repaired.

Different parts

The original 350 Manual engine was replaced with a 620 Signature Cummins electronic engine. This was sourced from a 2011 Freightliner that had previously caught fire and sold as parts. The radiator and gearbox also came from the Freightliner. The gearbox is an 18 speed Roadranger. All the original steel suspension was replaced with air suspension for a softer ride. The front springs were also swapped to air.

The sleeper was imported from America, it was originally black, and the paint was so thick they had to scrape it off! Graeme extended the bonnet by 300mm, purely to look good, then also extended the chassis by 2 metres to balance how the truck looked with the longer bonnet. To do this a new beam was cut and welded onto the existing chassis behind the cab. Alister and Geoff Duffy from RMD Marton helped put the cab on the chassis using a Hiab.

The original cab steel frame was rusted so was replaced with alloy and came from America. The upholstery was ordered and came from Seattle, USA then fitted in New Zealand. This process took two years! The cab is 1524mm wide.

The gauges, suspension and various other parts came from a Kenworth T404 in Tauranga. The air tanks also came from Tauranga out of an international truck.

The finish line

Although Graeme did a lot of work on the W924 himself, it wouldn’t have been a success without the help of many others.

Graeme spent many hours making cardboard cuttings for various parts including fabricated guards and the dash for the gauges. The cuttings were taken to Matt and Nick at Roadrunner Manufacturing in Bulls.

As the W924 started coming together, Graeme had mixed feelings of excitement and nerves. Excited because it was nearly complete and looking fantastic, and nervous because so much time and effort had been put into restoring it. He just wanted it to be a success and it was!

Driving it for the first time, Graeme can only describe it in one word – “WHEW!”

The first trip Graeme and his wife Raelene took was all the way down south to Invercargill. Graeme laughs that he took an abundance of spare bolts and tape just in case.

SPECIAL MENTIONS

PEOPLE INVOLVED IN THE REBUILD

*Brennan Chapman/Amerikiwi

Cab and chrome parts

*Geoff Duffy/TWL

Brakes and air

*Hugo and Peter/ Autokraft

Electrical

*Gwyn Bliss-Bennett & James Rooke/ Rangitikei Truck and Diesel

Setting up chassis with motor, gearbox and diffs

*Tony Poynter/Total Truck Spray

Painting

*Willy Malcolm/ Malcolm Cab Solutions

Refurbished cab and fitted upholstery

*Tony Walton/ Custom Art

Artwork and signwriting

*Matt Avery & Nick Webster/Roadrunner

Stainless and chrome fabrication

Graeme and Raelene have entered this “labour of love” in two truck shows and took away awards at both.

Professional Truck Photographer in the making

Our mate Thomas hails from Canterbury in New Zealand, and he loves loves loves taking photos of trucks!

I absolutely love trucks, and I love taking photos of them just as much!

I am 10 years old and I live in Canterbury, which is in the South Island of New Zealand.

I’ve been taking photos of some pretty cool rigs since I was around 5 years old, when my dad gave me my very first camera.

One of my favourite things to do in the school holidays and at the weekends when I’m not playing sport is to go with my dad on callouts in his tyre truck in and around Christchurch.

It’s so exciting when I see a big rig coming in the distance! I can usually tell what company, make and model it is and if I haven’t already got it, Dad will try and pull over if it’s safe to do so, so I can get a photo.

We go to some awesome places and truck yards and capture some cool trucking action!

My favourite truck make is a Kenworth, and I Iike the T909 and C509 models the most.

Here are some of my favourite pictures to share with you, I hope you like them as much as I do.

Keep on trucking! Over and out – Thomas.

‘Nothing Fancy’... I don’t think so!

It’s big, it’s fancy, and it carries a special message.

For this issue we are in Australia for the Top Truck, in a town called Julia Creek situated between Cloncurry and Hugenden in outback Queensland. (Why not see if you can find Julia Creek on a map? Then you know exactly where this big truck comes from).

Julia Creek is home to Tim and Sheree Pratt Cattle Transport, a two-truck livestock hauling business owned by husband and wife team Tim and Sheree Pratt, with loads of extra enthu- siasm and support coming from their three children, Abbie, Sam, and Bronté. It’s a family affair!

You can tell the family has a great sense of humour because our poster truck, one of two Kenworth C509 model trucks they own, is called ‘Nothing Fancy’! That will be the day.

The big blue and white Kenworth runs a Cummins X15 motor producing 448kW (600hp), with an 18-speed manual Eaton Roadranger transmission behind it.

It needs all that power and all those gears, because hooked behind are three huge Haulmark cattle trailers.

The truck carts cattle all over outback Queensland and into the Northern Territory. To keep the 62 tyres – plus spares – rolling through the vast country, the Kenworth carries 2000 litres of fuel on the truck, plus an 800-litre tank of fuel on each trailer. This fuel can be pumped into the truck’s fuel tanks when it’s getting a little low. It also holds 300-litre of Diesel Emission Fuel (DEF), a liquid used to help the big diesel engine run nice and clean.

To make sure Tim gets the rest he needs out on the long runs, there’s a 60-inch sleep- er on the truck, fitted with an ICEPACK air conditioner. You can see this machine in the pictures, it’s the small square box behind the sleeper on the left-hand side. Its job is to keep the sleeper cool without the need to run the truck’s big Cummins engine. Handy!

On the back of the last trailer you can see the hashtags #speakevenifyour- voiceshakes, #dollysdream, and #doitfordolly. They are there because the Pratt family are supporters of Dolly’s Dream, a programme created by Kate and Tick Everett whose daughter Dolly took her own life as a result of bullying. The Everetts and supporting families like the Pratts, work to prevent bullying in all its forms, and encourage young people being bullied to speak-up.

What great people, what a great machine.

Out on the job!

Ruby spends a lot of time out trucking with her stepdad, Reece. She shares some awesome photos out on the job!

Hey guys! I’m Ruby, I’m 10 years old and live in Balclutha, South Otago, New Zealand.

My stepdad Reece owns Cranleigh Haulage, a rural- based transport company. I’m lucky enough to spend a lot of time out trucking.

I love going in any of the trucks, but mostly the stock truck. I love to get in the back and use my stock whistle! When I’m out trucking, I mostly love the views and some of the scenic routes you get in the middle of nowhere, especially when doing stock.

I also love hanging out in the workshop and doing a bit of truck maintenance.

Other than trucking, I’m really into Moto-X, I’ve even got a motorbike that I get to ride often. I also enjoy art, and love rocks, minerals and all the information behind them.

Here’s some pics of me out on the job!

Talley’s pea run with Jack

Nine-year-old Jack recently went on the Talley’s pea run, and got to see how the peas are harvested, how they are transported, and what happens at the factory.

I went with my friend’s grandad, Greg, to do the Talley’s pea run in a 2018 R480 Scania.

We went down to a farm in Rakaia for the pea harvest. We worked with a harvester, a John Deere tractor towing a chaser bin, and some other Scania trucks. It was muddy!

The harvester picks up the whole plant and shreds it through until it’s just the peas – the rest comes out the back and lands in the paddock. The harvester drops the peas into the chaser bin and then the John Deere takes them to one of the trucks. The John Deere gets very close up to the truck and then the hydraulics push the chaser bin up to drop the peas into the back of the truck. Then the load of peas is ready to go to the factory.

Next, we headed down to the Talley’s factory. At the weighbridge, we got weighed, then a computer records which truck we were in, what we were carrying and who was the driver.

Greg backed up and tipped the load of peas into the hopper ready to go into the factory and be bagged up to be sold in shops in New Zealand and around the world.

Finally, we washed the dusty and muddy truck. Today was a great day in the Scania R480. I would love to do it again.

Trip to Golden Bay

Hey Little Truckers, I hope you have all had a great Christmas and New Year! I have been quite busy these holidays but I still managed to fit a really cool trip in.

On Christmas Eve 2021, I jumped in the cab with Dad, and we made our way over to Takaka, Golden Bay to complete a delivery and load up. We headed off at 6am on a journey of just over an hour, made a bit quicker than last time as the roadworks on the Takaka Hill had finally been completed after damage from Cyclone Gita in 2017.

We made it to the Sollys Depot on Commercial Street where we tipped the trailer load of palm kernel off in the bulk store.

We unhooked the trailer and went to a farm at Hamama. When we arrived, we started to unload the truck load of palm kernel. Palm kernel is popularly used as stock food for cattle. I had the pleasure of meeting a very friendly calf there, who came over to say hello, while Dad worked on unloading.

He tipped half the load off before jumping out and borrowing the farmer’s tractor, to push the kernel up into the back of the shed. He was then able to tip off the other half of the load. He did this because the shed was too low to tip straight into and tipping it off altogether would result in a big mess, leaving the kernel out in the weather! This is a practice for many truck drivers, with some customers often leaving their tractors, forklifts, and loaders nearby for them to use. Drivers being able to drive tractors, forklifts and loaders are skills that many drivers learn early in their career.

I farewelled the calf and we made a quick trip back to Sollys depot to hook up the trailer. Shortly after we bounced on up to the Golden Bay Dolomite plant located at Mount Burnet at the northwest corner of the South Island. The views out to the Tasman Sea and along the coastline, from the deck of the site office there, are beautiful. While I was playing photographer and catching some action photos, Dad got on the loader and packed the bins full of dolomite. This load was headed for Canterbury, between Christmas and New Year. Before heading back over the Takaka Hill with its 360° corners, we stopped back at the Sollys depot for a drink, something off the barbeque, and a catch-up with some of the drivers who were enjoying the staff Christmas Eve shout. We made it back home to Motueka for lunch with the family eagerly awaiting Christmas the next day. All in all, this short half- day trip was efficient and accomplished all that was needed, while affording me a meeting with a very cool furry friend.

I look forward to the next trip!

Stuart Drummond Transport

In our regular Meet My Fleet feature, Milly McCauley catches up with a transport operator to learn about their company and fleet of trucks. This month, she met up with Brodie Drummond of Stuart Drummond Transport from Richmond, near Nelson.

Who owns Stuart Drummond Transport?

Stuart Drummond Transport is a family-owned company, founded by Brodie’s dad Stuart, and today owned by the Drummond family.

What type of loads do you cart?

Stuart Drummond Transport is a solely log cartage company. They cart to sawmills, an MDF factory, and to the ports at both Nelson & Picton, where the logs are exported overseas.

How long has the transport company been in business?

The company has been in business for 36 years.

How many trucks are in the Stuart Drummond fleet and what brands do you have?

Stuart Drummond Transport operates 55 trucks, and their fleet consists of 18 Kenworths, 11 Freightliners, 2 Western Stars, 5 Scanias, 8 Hinos and 11 DAFs.

How many people does the company employ?

Stuart Drummond employs 70 people over their management, administration, workshop and driving fields.

Did you always think you would work in transport?

Brodie says growing up around his dad and trucks meant he always knew where he wanted to be. With his childhood involved in transport, it was an easy choice to make.

Where are the main areas you operate in around New Zealand?

Stuart Drummond Transport operates all over the top half of the South Island.

What is your title at Stuart Drummond Transport?

Brodie is the general manager of Stuart Drummond Transport.

How long have you been involved with the business?

Brodie has been involved with the company for 14 years. He started in 2007 and has worked his way up to general manager.

What’s your favourite thing about working in the industry?

The best thing would be meeting all different kinds of people.

What things would you like to see change for the transport industry over time?

Brodie says he would like to see more young people getting into the industry. He says succession within the industry is important, with many older, experienced drivers reaching retirement age in the next few years.

Do you have a favourite truck in your fleet?

The company’s Kenworth T900.

Can you tell me a fun or interesting fact about Stuart Drummond Transport?

The company is on track to travel 4.4 million km this year and cart more than a million tonnes of logs.

What would be some advice you would give to any young people who want to start a career in transport?

Start early with getting your licences, get the ball rolling. The transport industry is a great opportunity for young people to get ahead, as long as you are prepared to do the work.

Are all your trucks based in Richmond or are there other locations?

Stuart Drummond Transport has trucks based throughout the top of the South Island as well as on the West Coast and in Marlborough. Their main yard, workshop and headquarters are in Richmond.

Truckers, Rocks and Diggers!

Our friend Kaitlyn got to spend the day out and about with Christchurch-based Road Metals, a company that works with gravel, sand and other products for lots of roading and construction projects.

My name is Kaitlyn Stewart and I am 10 years old. I got the opportunity to go out to Road Metals in Rolleston to see what goes on out there.

We were met by Aaron McGrath, who told us how Road Metals work with aggregates and are involved in the production of sand as well.

He showed us around the museum of the firm. He has been working for the company for one year.

I got to sit in the trucks and diggers in the museum.

We really enjoyed the museum and learning facts about the company.

Aaron offered to take us out on one of the trucks to see what they do. We went with Marty Grainger, who has worked for the company for 10 years. We got to pick up 14 tonnes of aggregate and go for a drive out by McCleans Island to the branch there.

It was such a nice day and Marty told us all about the buttons and what they did. I got to push the engine button that helped slow the brakes down. They have a system where they are tracked with their speed. They can’t go over 90kph or a red truck comes up on the screen.

I saw how they dumped the aggregate and we picked up a fresh load. Marty told us it costs about $600 a day to fill the truck. We couldn’t get out of the truck due to health and safety.

When we were coming back we got stuck in sheep traffic. I had so much fun learning about trucks.

Thank you Road Metals for the experience and merchandise!