Overnighter in a K200

His first time in a K200, Dustin went on a neat overnight roadie with his dad, seeing some cool spots along the way.

One drizzly sum- mer morning at 3:15am, there were alarms going off. I sprung out of bed and went out to the kitchen. I went into the pantry and grabbed some Weetbix, and I even made some for Dad.

We got in the Kenworth K200, which has a 600hp Cummins engine, in the Christchurch yard and took a load of empty pallets down to Timaru. It was my first time in a K200, so I was pretty excited.

We unloaded and reloaded, and headed north for Nelson. We stopped in Hinds and saw my Nan. After that we carried on, and we stopped in Amberley and got fuel.

Our next stop was Maruia Falls where we had a half- hour break. Did you know Maruia Falls was created in 1929 in the Murchison earthquake? That’s pretty cool.

After a quick break we carried on and went to Brenics’ yard and parked the truck up. We went to the motel and l had some tea, then we watched some TV before we went to bed.

The next day we woke up and went and dropped off the load at Sollys. After that, we went back to the yard and we got another load of veggies that from Friday afternoon would end up in Invercargill – the whole length of the South Island by Saturday morning!

We pointed south, we stopped in Springs Junction to get some water, and then we carried on to Christchurch. We got unloaded, and that was the end of our fantastic trip.

A special thank you to Brenics Ltd for letting Dad drive, and to everyone else along the way who were all super helpful and very friendly.

It’s like a big jigsaw puzzle!

One year into the job, we get to know Michael Baylis over at Kennedy Trailers who tells us all about being an apprentice boilermaker.

Michael’s job as a boilermaker is to weld steel together to make trailers. He works off a drawing that shows him which pieces need to go together. It’s kind of like a big jigsaw puzzle.

Welding is a very fine art, it takes lots of practice, patience and precision to get your welds nice and straight and strong. If you leave the welder in one spot for too long, it burns a hole straight through – but if you don’t leave it long enough, the trailer will not be strong enough! So it’s safe to say that the welder has a lot of responsibility and needs to be concentrating at all times.

When a welder gets the perfect weld, it is a great achievement.

Little Trucker: How long have you been on the job?

Michael: I started my apprenticeship 2.5 years ago and have been at Kennedy Trailers for just over a year.

Little Trucker: What are some of your main responsibilities?

Michael: One of my main responsibilities is fabricating cabguards.

Little Trucker: What kind of training did you do for your job?

Michael: I’ve been attending trade school and they provide my training as well as learning on the job.

Little Trucker: What is your favourite thing about your job?

Michael: I most enjoy fabricating and getting to learn new skills and put them to use.

Little Trucker: And what is your favourite type of truck?

Michael: I find heavy-haulage trucks pretty interesting!

Little Trucker: What are some of your hobbies outside of work?

Michael: Outside of work I spend my time fishing, 4WD, or camping. I also like country music.

Safety tips for our road users

It’s not just those behind the wheel of a truck that need to think about safety while using the road. Whether you’re out for a walk, on a bike, or driving a car, there’s lots of things to think about!

TIPS FOR PEDESTRIANS

Walk on sidewalks, watch out for blind spots, and keep alert at all times! Don’t be distracted by electronic devices and make eye contact with drivers. And make sure you watch for trucks entering, exiting or backing up in parking lots and at job sites.

DRIVERS PASSING A SEMI-TRUCK

It takes truck drivers much more time to stop than you - so keep a safe distance. They have bigger blind spots, so pass on the right side, at a safe, steady speed, and make sure you’re well beyond the truck before getting back over.

TIPS FOR CYCLISTS

Look out for trucks turning left from beside or behind you. Don’t stop too close to the front of a stopped truck. Never cycle up the left side of a truck stopped at a junction.

APL Direct

They are an impressive head-turing sight wherever they are spotted. Milly McCauley was lucky enough to spend some time with APL Direct’s general manager Jake Lambert and meet the man in charge of one of the country’s sharpest line-haul fleets.

LTDU: Who owns APL Direct?

Jake: APL direct is owned by the Plaw family.

LTDU: How long has APL Direct been in business?

Jake: APL Direct was established in 2003 and started out as a small aluminium joinery fabrication company. As APL grew, they faced problems and damages with third-party distributors, deciding therefore to take the distribution of their product into their own hands. APL Direct has now been operating for over 19 years.

LTDU: Where do you have trucks based?

Jake: APL Direct has four main depots; Hamilton, Hautapu, where the glass operations are based, Palmerston North where a smaller satellite depot is, and Christchurch where we service the South Island from.

LTDU: How many trucks does APL Direct operate?

Jake: APL has 38 trucks and 15 trailers in the fleet. This number is continually growing!

LTDU: What makes of trucks do you have and how many of each?

Jake: The APL Direct fleet is mainly Scania, however Hinos and DAFs are there also, used for smaller metro delivery services.

LTDU: How many people do APL Direct employ?

Jake: APL has more than 60 employees throughout their dispatching, management and transport divisions.

This number has grown substantially throughout the last years as APL Direct expanded with the growth of the glass business in particular.

LTDU: What type of loads do you cart?

Jake: APL predominately carts aluminium extrusion, hardware, rubber coils, sheet metal and glass.

LTDU: Where are the main areas you operate in around New Zealand?

Jake: APL delivers from Keri Keri in the north all the way down to Invercargill in the south, servicing a large expanse of fabricators throughout the country.

LTDU: What is your title at APL Direct and what are your responsibilities?

Jake: I am the general manager overseeing the whole operation at APL Direct.

LTDU: Did you always think you would work in transport? Jake: No, I never thought I would work in transport but when the opportunity arose, I jumped at the chance. It was something completely different.

LTDU: How long have you been involved with the business?

Jake: I have been working at APL Direct for five years, and in this role for just over three years.

LTDU: What’s your favourite thing about working in the industry?

Jake: Being able to provide people with opportunities, watch them grow in their work, and see their personal development.

LTDU: What things would you like to see change for the transport industry over time?

Jake: I would like to see more done towards alternative energy, actually trying to narrow down which way the industry will head is a big issue. I would like to see some proper direction as we work towards a more sustainable future of transport.

LTDU: Do you have a favourite truck in your fleet?

Jake: No, no favourites in particular, I just like that APL Direct trucks are quite unique, noticeable and well presented.

LTDU: What would be some advice you would give to any young people who want to start a career in transport?

Jake: Having a good work ethic and a good attitude will get you a long way especially in this industry. Spend some time around people in transport and put yourself out there, as there is always opportunity to grow and progress.

LTDU: Can you tell me a fun or interesting fact about APL Direct?

Jake: The fleet runs 95% Euro-5 or better, with 40% now Euro-6. We are working hard on increasing Euro-6 numbers. APL Direct focuses heavily on sustainability, and is working on a number of recycling initiatives throughout all products and packaging.

If It's broken we fix

No two days are the same for apprentice mechanic Natarsha Smith, who is working hard to become a specialist in heavy diesel machinery.

Natarsha works as an apprentice heavy diesel mechanic at Hyster NZ, which provides a range of fork- lifts and other handling solutions to business.

“We’ve got about 20 machines at this site with forklifts ranging from two and a half tonne right up to twenty-five tonne,” she explains.

“We fix anything on the machines that can break - so anything from the front mast to the hydraulics and the electrical and mechanical side. Whatever’s broken, we fix it – you never know what you’re going to get!”

With a day so varied, it’s no surprise that Natarsha’s favourite part of the job is problem-solving. “When you’re not sure what’s wrong and you figure it out, that’s the best.”

Study study study Natarsha’s been working at Hyster NZ in Mount Maunganui for two and a half years and is well on her way through her MITO New Zealand Certificate in Heavy Automotive Engineering. The course is designed for people interested in servicing and repairing electric and non- electric forklifts and other machinery used for moving and storing materials, goods and products.

“There was a job in Tauranga for materials handling and I thought that sounded pretty cool, so I applied and here I am! I’m really grateful it worked out the way it did. It feels like one of those things in life that’s meant to happen.”

Not just for boys

Natarsha says that despite lots of people thinking the heavy diesel industry is just for boys, it’s not true.

“The opinions of having girls doing this kind of work is improving greatly and I get really positive feedback. Especially in heavy diesel, people think it’s going to be hard work and a lot of heavy lifting, but if something weighs too much, there’s always another machine that you can use to lift it,” she says.

“I would definitely recommend this industry to anyone. It’s a lot of fun!”

Visiting the Truck Hospital

Max and his brother Miller love to visit their grandad who works as a diesel mechanic. They love to climb on the trucks at what they call the truck hospital.

My name is Max Ludman and I’m 5 and 3/4 years old and I love big trucks.

My grandad is a mechanic for Hick Bros Civil in Silverdale, Auckland. I love going to the yard to see all of the different trucks and diggers.

This is their Western Star Transporter. There is a Caterpillar 815 Compactor on the trailer. The cab was very high and I sat on the red leather seat. It had a wooden steering wheel! We looked under the bonnet and saw the engine, which is a Caterpillar C15.

There were lots of different machines in the yard, the biggest were two Caterpillar 627 motor scrapers.

I can’t wait to see what trucks are there next time I visit again with my little brother, Miller.

Safety first, seat belt on

Our author in action Jesse keeps us in the loop with all things safety when he goes out on the truck.

First of all, welcome to my trucking adven- tures. Safety first, so remember to put your seatbelt on.

I’ve been trucking with my dad Mike since I was born. He works for Pyramid Trucking and drives a Kenworth T610 SAR. He used to drive a Kenworth K200, but that’s off the road now.

When I get ready for a day out on the truck, I need to make sure I have my Hi vis gears, work boots and definitely enough lunch for my day.

When I’m at work with Dad I get to do a few things with him, like washing the truck, rolling straps and the fun stuff of going out with one of the office girls to get donuts. My main job at Dad’s work is just to keep safe, and enjoy the time with him.

What I really enjoy about being allowed to go out on the trucks is that I get to see a lot of different places I haven’t been to before, as well as seeing all the awesome rigs on the roads. Also getting waves back from other truck drivers (I think I’ve perfected my trucking wave!).

I have a few different trucks I really like, but I think they are all awesome. The ones I like seeing on the road are Kenworths, Macks and Freightliners.

When I leave school I really want to be a truck driver like Dad and my big brother, who also drives trucks.

Mini Truckin

Hey kids, wanna drive your own rig? Check this out!

Have you guys seen this cool mini rig on social media yet? Owned by Heikell Transport in Whakatane, the mini ride-on Scania is made by a company in Ireland called Scaled Rigs, and Heikell’s added it to its ‘fleet’ in 2020.

Then, early this year, stock- crates builder Nationwide Stock Crates from Mount Maunganui (which builds all the crates for Heikell’s fleet of stock trucks) handed over the custom tri-axle semi-trailer, completing the rig. Nationwide made sure the trailer is all kid-friendly, ensuring there are no sharp edges or surfaces that could cause harm – just like it does for the real crates that cart animals.

Both the truck tractor and trailer are done in full Heikell Transport livery. The awesome graphics on the side of the mini-Scania are a replica of that on fleet No.16, a Scania S650 8×4 known as ‘Legend II’.

There’s even working lights behind the cab and on the trailer – just like the real thing! It has real pneumatic tyres (meaning they’re filled with air), is battery powered and has forward and reverse gears. It’ll do a top speed of 6kph, more than enough to have some good fun. And, when you put your foot down, the truck makes a realistic sounding engine noise.

Now that’s a cool toy!

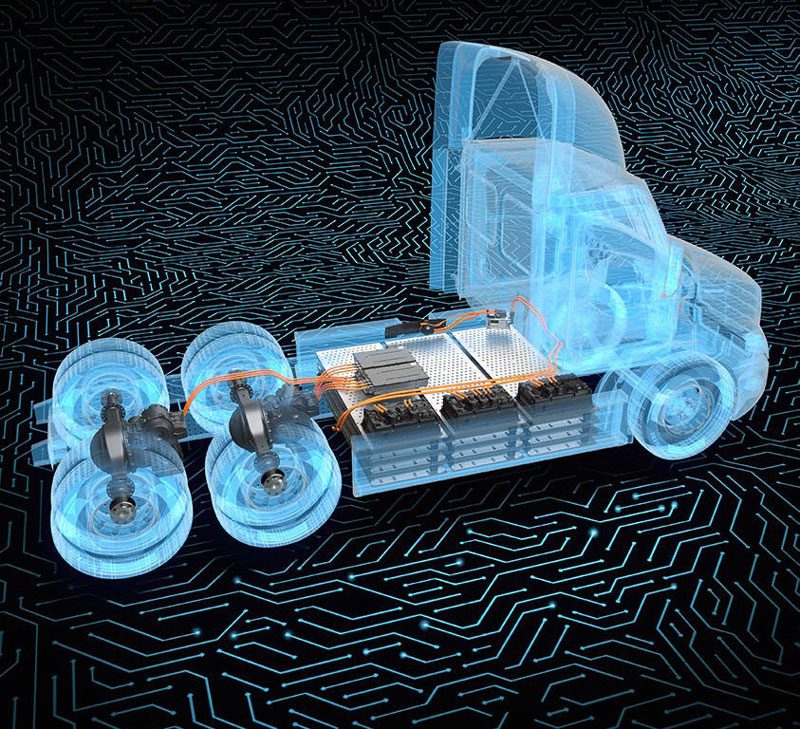

Everything you need to know about Electric Trucks

What is an electric vehicle? Why are they a good option? Are they the future?

What is an electric vehicle/truck?

The electric automobile is a motor vehicle powered by rechargeable batteries rather than fossil fuels. Petrol and diesel are fossil fuels.

Why electric trucks?

Electric vehicles are more energy efficient and have a lower environmental impact. The environmental impact of an electric truck is very low when the truck is in use, in fact they produce zero emissions on the road and are very very very quiet. They are so quiet, manufacturers have to add sounds to the vehicles to ensure pedestrians and cyclists can hear them. EVs are energy efficient. They convert more than 77% of the electrical energy from the grid to power at the wheels. Conventional diesel or petrol vehicles only convert about 12%–30% of the energy stored in fossil fuel to power at the wheels.

Electric Trucks Down Under:

The eCanter, an electric truck from FUSO, is the world’s first series-produced, fully electric light truck that is available in the New Zealand market. It is ideal for inner-city deliveries.

There are many manufacturers developing and road-testing battery- electric, heavy-duty electric trucks such as the eActros from Mercedes-Benz and eCascadia from Freightliner, so expect to see more electric trucks on Australian and New Zealand roads in the not-to- distanced future!

Restoring a classic truck Part 1

1997 Kenworth W924 – A labour of love with Graeme Skou.

We all enjoy seeing trucks on the road and at shows that make us go WOW!

Have you ever wondered how they get them looking so flash? How much work goes into them? How are they put together? I may be able to answer some of your questions!

I met Graeme Skou and he has shared two of his rebuild stories with us. Today we will look at his 1977 Kenworth W924.

Graeme has always been a Mack man at heart, but he chose to rebuild a Kenworth W924 because they look good and have strong bones. He bought the truck in 2016 and it took him five years to restore. It was never his plan to take that long, but due to the truck previously living near the ocean there was quite a bit of corrosion/rust that needed to be repaired.

Different parts

The original 350 Manual engine was replaced with a 620 Signature Cummins electronic engine. This was sourced from a 2011 Freightliner that had previously caught fire and sold as parts. The radiator and gearbox also came from the Freightliner. The gearbox is an 18 speed Roadranger. All the original steel suspension was replaced with air suspension for a softer ride. The front springs were also swapped to air.

The sleeper was imported from America, it was originally black, and the paint was so thick they had to scrape it off! Graeme extended the bonnet by 300mm, purely to look good, then also extended the chassis by 2 metres to balance how the truck looked with the longer bonnet. To do this a new beam was cut and welded onto the existing chassis behind the cab. Alister and Geoff Duffy from RMD Marton helped put the cab on the chassis using a Hiab.

The original cab steel frame was rusted so was replaced with alloy and came from America. The upholstery was ordered and came from Seattle, USA then fitted in New Zealand. This process took two years! The cab is 1524mm wide.

The gauges, suspension and various other parts came from a Kenworth T404 in Tauranga. The air tanks also came from Tauranga out of an international truck.

The finish line

Although Graeme did a lot of work on the W924 himself, it wouldn’t have been a success without the help of many others.

Graeme spent many hours making cardboard cuttings for various parts including fabricated guards and the dash for the gauges. The cuttings were taken to Matt and Nick at Roadrunner Manufacturing in Bulls.

As the W924 started coming together, Graeme had mixed feelings of excitement and nerves. Excited because it was nearly complete and looking fantastic, and nervous because so much time and effort had been put into restoring it. He just wanted it to be a success and it was!

Driving it for the first time, Graeme can only describe it in one word – “WHEW!”

The first trip Graeme and his wife Raelene took was all the way down south to Invercargill. Graeme laughs that he took an abundance of spare bolts and tape just in case.

SPECIAL MENTIONS

PEOPLE INVOLVED IN THE REBUILD

*Brennan Chapman/Amerikiwi

Cab and chrome parts

*Geoff Duffy/TWL

Brakes and air

*Hugo and Peter/ Autokraft

Electrical

*Gwyn Bliss-Bennett & James Rooke/ Rangitikei Truck and Diesel

Setting up chassis with motor, gearbox and diffs

*Tony Poynter/Total Truck Spray

Painting

*Willy Malcolm/ Malcolm Cab Solutions

Refurbished cab and fitted upholstery

*Tony Walton/ Custom Art

Artwork and signwriting

*Matt Avery & Nick Webster/Roadrunner

Stainless and chrome fabrication

Graeme and Raelene have entered this “labour of love” in two truck shows and took away awards at both.