The big T610 Kenworth

One rainy afternoon I jumped in the big T610 Kenworth with truck driver Matt from Steve Martin Contracting, and I was on my way to Nelson.

As we pulled away I could hardly tell that we had a load on – the truck boasted 600hp and we were carrying 30 tonnes of flour.

As we were leaving Christchurch, we didn’t know if we were going up the coastline or up the Lewis Pass, because the road could have been closed because of snow. But Matt made the call and we went up the Lewis Pass – the road hadn’t shut so that was good news!

It was my first time in a T610 Kenworth. The truck does about 5500 kilometres a week. Steve Martin Contracting has four trucks. Matt said he has been truck driving for 22 years. It takes about one hour to unload and about 45 minutes to load the T610. Matt likes the truck’s power and it is a manual gearbox. Matt says he prefers black mud flaps over white mud flaps. My favourite thing about the truck was the cool green LED lights, which looked awesome at night.

Thanks Matt for taking me along for the ride, and to Steve Martin, his wife Robyn and the entire crew at Steve Martin Contracting.

Smarter Trucking: What is Fleet Management?

When a company has more than one vehicle, it is important to keep track of all their movements and activities, and make sure all the vehicles are in good, working order. This is called fleet management. Many companies use software that helps them with their fleet management, using technologies such as GPS and analytics.

Having good fleet management processes in place helps a vehicle stay on the road for longer. Here are some of the benefits of fleet management:

• Identifies any potential issues

• Increases a vehicle’s productivity and efficiency

• Reduces fuel costs and saves money

• Helps reduce negative impacts on the environment

• Locates and tracks vehicles while on the road

• Improves driver safety

Safety first

We spend a day at the Compliance and Safety Centre with Senior Constable Ian Deane and the team at Ohakea.

Keeping our trucks and drivers safe is a very important part of our job, says Senior Constable Ian Deane. Ian used to drive trucks but decided in 1997 to join the New Zealand Police Force and has been attached to the Commercial Vehicle Inspection team for the last 14 years. He joined to help people, and enjoys the flexibility of the job and the relationships he has built with truck drivers over the years. This shows as I see them go through smiling, waving, and some even stopping to chat.

One of Ian’s teammates, Constable Barry Vinten, was already at the office when I arrived and the “All Trucks Stop“ sign was on letting truck drivers know to pull in on their way past for a quick weigh check to ensure they are travelling safe and within the requirements of the law.

If all is well, it is a very fast process where they drive up to the red light by the office where the scales are and drive over. The weight is logged on the computer inside so the constables can check details. If everything looks good then the driver gets a thumbs up, the light turns green, and the driver carries on with his day.

If there is an issue, the driver is asked to pull over and the constable will look further into the matter and if needed fill out a commercial vehicle inspection report.

Senior Constable Deane turns up with cookies and milk! We have a cuppa and talk about some of the things they do.

Weighing the trucks is important as there are limits to how much they can carry safely. Without going into too much detail, they have a list of different axle sets and lengths of vehicles that determine how much each vehicle can carry. For example: an 8 axle truck could carry 46 tonne gross weight, or a 9 axle truck could carry 50 tonne gross weight (with a permit it could carry up to 58 tonne).

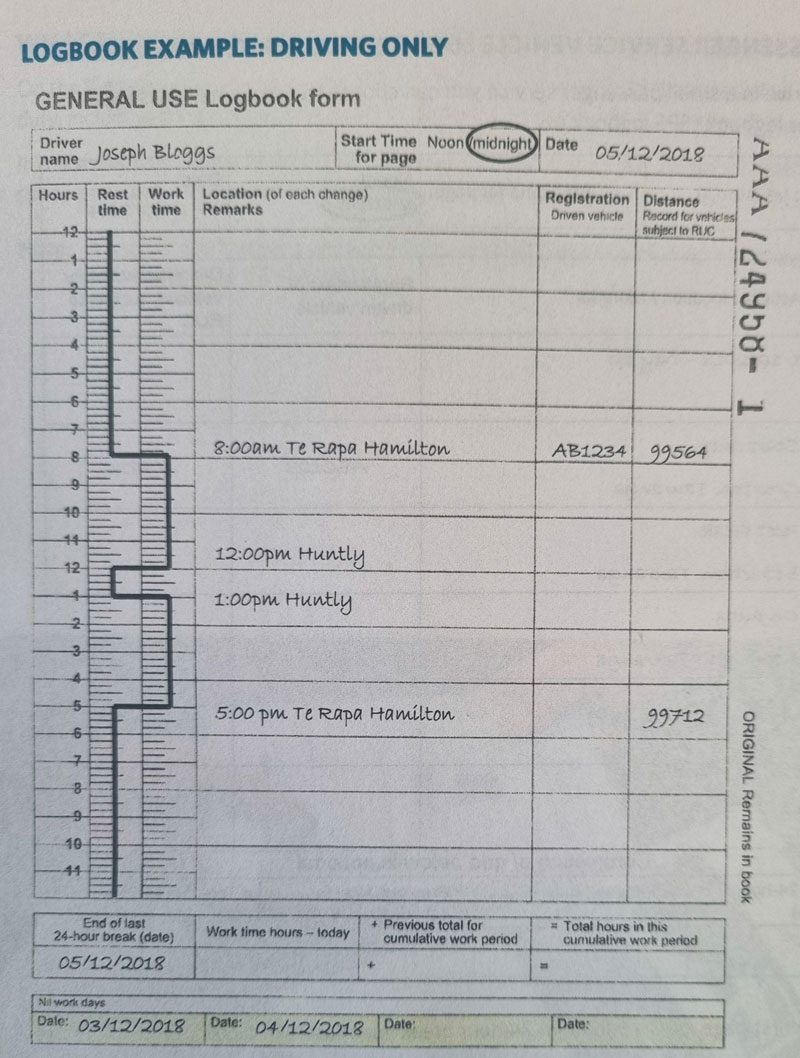

But there is more to a Commercial Vehicle Safety inspector than just weighing the trucks. They also check for vehicle defects, things that may be broken or need replacing. The safety of the vehicle can include things like tyres, lights and suspension. Then there is vehicle fitness, they check to see that they are up to date with registration and road user fees and that it has a current COF (certificate of fitness) – this is a safety check done every six months to ensure everything on the truck is working properly. Dangerous goods are another thing that may need checking. Making sure the load is secured/loaded properly. And logbooks, these are a documentation of the hours a driver works with compulsory break and stop times to ensure they get rest and don’t work too long and get too tired. A truck driver can legally drive up to 70 hours in one week. That’s a lot of time trucking! They can work no more than 14 hours in one day including two half hour breaks where they can eat a meal, stretch their legs and have a breather. They must then have at least a 10 hour rest/sleep period. Once 70 hours is worked, they are required to have a minimum of 24 hours off work.

Truck drivers have huge responsibilities, and it is the duty of our Commercial Vehicle Inspection Officers to ensure they are doing their job safely, securely and legally. They are also there to help. Because they are very knowledgeable in their area of expertise drivers, truck owners/operators etc can call on them to answer any questions or enquiries regarding the legal aspects of their work.

There are around 12 Compliance and Safety Centres around New Zealand, and multiple more weigh pits where the officers use portable scales. All weigh bridges are calibrated 12 monthly. This means they are carefully assessed, set and/or adjusted. This is to make sure they are accurate and give correct readings.

Located across from the weigh bridge office are the Highway Patrol (Road Police) and administration offices. Today I saw two of these police officers called away because a truck had veered off the road. Their job is to assess the scene/ area and see what factors may have contributed to this happening and write up a report.

Smart Trucking

Our on-the-ground reporter in Australia Mike Williams tells us all about telemetry – which is special equipment used to record what a truck is doing on the road.

G’day there Little Truckers. There are a lot of interesting characters in trucking in New Zealand. We have a few in Australia as well. My friend Rod Hannifey is one of those. He works for Rod Pilon Transport in Dubbo in New South Wales.

Rod is a long time road safety advocate with probably the smartest truck in Australia. I don’t mean smartest as in best looking either, although it does look good, I mean the smartest as in it has lots of hi tech equipment to record what the truck is doing on the road. This is called telemetry. You normally see that on race cars. Rod records all the data from the road and the truck and shares that to help make our roads safer.

He’s driven all over the place and carried all sorts of freight. When I last saw him he had a “B Triple” hooked up heading for far North Queensland.

Let’s have a look at the Transport Industry Vehicle that Rod drives to promote road safety and collect the telemetry data he shares.

All aboard the Grain Train!

Reid heads out in a Scania with our friends at Owens Transport, carting grain to Auckland to make beer!

Hi there Little Truckers, my name is Reid and recently I had my second adventure in a big rig truck.

This time I was in a V8 R620 Scania with Shaun and Ben from Owens Transport.

As Shaun pulled up, I felt amazed and shocked at the same time because of how big the Scania was and that it was a curtain sider. Today’s job is to cart grain to an Auckland brewery to make Heineken beer.

Shaun drove into the Tatuanui weighbridge to pick me up. The Scania is a truck and trailer that holds a big bag inside filled with grain. It was weird because there is not normally a big bag inside a curtain sider. Big tanks store all the grain before loading the trucks. It gets loaded up the top. There’s a remote that tips the deck up and down when the truck is unloading the grain. When the truck’s deck tips, the grain goes out the little doors at the back.

I am really grateful to Shaun and Ben who took time out of their day to take me for a ride and for answering my questions! What an epic day riding in the big gear!

A day out with Dad

I started the morning by attempting to mirror my father’s normal daily routine. A 4am wake up call, breakfast, preparing for work and then the drive to Swanson from Mangere.

My dad Kiripati is the general freight manager for Swanson Transport Ltd. General freight handles and transports a wide variety of goods that can be transported in many ways. They can either be transported in containers, vans, trucks and trailers and sometimes even specialised vehicles.

The general freight trucking industry provides a number of key services such as local pickup, local sorting, destination sorting and local delivery. Communication and planning plays a pivotal part in performing his role. The numerous emails and phone calls received can vary from internal and external customers, new customers requiring freight services to drivers who will require location confirmation and any special delivery or pickup instructions.

Order and truck allocation is key to ensure that the right vehicle is sent to perform the right job. Certain truck operators hold different class licences, so my father needs to identify these special jobs and select the right operator to perform the duty.

Every day is different, so planning ahead to keep on top of the ever-changing schedule is important to ensure things run smoothly for himself and his team. My dad’s role requires him to work in the office, ensuring that he is always available to tend to his customer and team needs. He is very hands-on and will happily assist if need be in the warehouse, operating the forklift and loading trucks.

Swanson Transport has their own mechanical workshop for their trucks on site, as well as their own wash bay. There are many trucks, all different types and sizes that perform special jobs. Some trucks have a fitted crane at the back, which allows them to lift extremely heavy and large loads. There are also pilot utes that guide larger trucks – they are responsible for alerting the truck driver of any possible issues ahead and ensure other road users are aware that a large heavy load follows.

Safety is taken very seriously at Swanson Transport, certain safety gear is required to move around the workplace. All visitors are required to sign in on arrival and access must be given to enter the work site. Hi-vis vests, hard hats and safety boots are to be worn, most importantly being aware of your surroundings and recognising possible danger.

I have enjoyed my time at Swanson Transport, witnessing first hand Dad’s work day and the pride he takes in his work.

I had the privilege of meeting the owner of the business, Mr Jeff Smith, who has been part of this business for many years. I also met general manager Mr Nick Longuet-Higgins, as well as the office staff who were all very welcoming. Now that I’ve had an insight into how the transport industry operates, next time I see a truck on the road I’ll definitely be giving it a wave! Thanks to Dad and everyone at Swanson Transport for showing me around.

Photo Tips and Tricks

Junior truck photographer Thomas shares some top tips on how to take a great truck photo

Rain, snow or sun-shine, you’ll find me out and about in all sorts of weather, snapping photos of cool rigs hauling in and around Canterbury.

Here’s a few top tips I’ve learnt for a good roadshot.

I make sure my camera is on the right setting for most of my photos. I use the sports mode as I find it suits the fast moving trucks the best.

The best thing about roadshots is you can pick your background and find some really nice spots to take your truck photos.

I also look for where the sun is and try to get the sun on the front and side of the truck. This is very important unless it’s an overcast day.

On overcast days I can shoot trucks going in both directions with an even lighting.

Timing is quite important as well, as cars and other traffic sometimes get in the way.

Timing is everything when it comes to roadshots. Here’s a few of my favourites I’ve taken over the last year…

Keep on trucking! Over and out, Thomas

Give us a wave!

Our mate Sally, who runs Tippings Transport in New South Wales, tells us all about her special campaign, Wave to a Truckie, which shines a spotlight on the amazing work our truckies do.

Who doesn’t love waving at truckies going past – even better when they sound their horn! YES! Truckies love being acknowledged for the important work they do and waving is a great way to say thank you.

A few years back, I founded a campaign called “Wave to a Truckie” to highlight and promote our dedicated truck drivers and the amazing work of all the people involved within the transport industry.

Everything we have in our homes, schools, hospitals – in fact everywhere – is delivered at some stage by a truckie and sometimes people take that for granted.

During Covid-19 lockdowns, people started to really understand the importance of the transport industry and the key role truckies played in delivering essential items to everyone’s home and office.

It takes lots of hard work and skill to become a professional truckie. It isn’t an easy job and is not suitable for everyone, however the rewards are endless.

Out on the open road, seeing the changing landscape, witnessing amazing sunrises and incredible sunsets are all so much more enticing than a small crowded office space. It really is like being your own boss.

Next time you see a truckie on the road, think about what is on their load and where it is going. Are they very far from home or will they be home for dinner?

Most importantly, when you can, make sure you Wave to a Truckie!

A cowbus from the Waikato

The Waikato region is well known for many things including the Chiefs rugby team, huge numbers of dairy cows…and it’s home to the Little Trucker Down Under Top Truck for Spring 2022.

This 2018 model Kenworth K200 Aerodyne is one of two trucks operated by Herring Haulage Limited of Morrinsville, right in the heart of the Waikato, working under the stunning blue, silver and bronze Nationwide Livestock Ltd colours.

Nationwide Livestock trucks are seen travelling all over New Zealand. The truck and its Jackson Enterprises five-axle trailer are fitted with matching Nationwide stock crates that allow them to carry two decks of cattle or up to four decks of sheep. Depending on the size of the animals, up to 600 sheep or 50 cows can be carried in a single load!

A Cummins X-15 engine produces 615 horsepower and gets the power to the rear wheels using an Eaton-Fuller transmission with 18 gears.

Many custom additions have been added to the Kenworth, ensuring it’s a real standout on the road. These include a painted diesel tank with nice line work on it, shiny stainless-steel air-intakes and a sun visor, plus a substantial polished aluminium bullbar, complete with the COWBUS personalised number plate.

If you see the big blue Kenworth cruise by, give the driver a wave – chances are, some cows are on board the coolest COWBUS around!

Wash time

With trucks all over New Zealand taking a battering from winter weather conditions, keeping your truck clean is important, not only because it looks nice and positively represents the industry, but also it can make spotting any maintenance issues easier than if it’s plastered in mud, dirt and grime.

Hi Little Truckers, I hope everybody is well and you are all keeping warm over winter. I have had a busy few months and there has been no opportunity to do a truck trip with Dad unfortunately.

However, I jumped at the chance to head over to Sollys Richmond Depot recently to meet up with Dad and help him wash the winter’s grime off the Scania.

Mum drove me across to Richmond, I caught up with Dad and after being shown the controls and what to do I was able to drive the Scania onto the wash pad…..what a thrill!

We wet the truck down, then sprayed it with detergent from the foam gun, before sponging the cab and wheels and scrubbing the rest of the unit with a soft brush.

Dad and I then had ‘turn-about’ using the water blaster to clean off the loosened dirt. As we worked our way around the truck and trailer, I asked Dad if he liked washing his truck.

“It’s certainly not my favourite part of the job but I like the finished result,” he said.

I think he secretly hopes I will offer to clean it each week!

We left the Scania to dry in the sun and headed to the smoko room where Dad said he ‘would shout me a cup of tea’ for helping with the washing.

On our way across the yard, I saw Leighton using an interesting-looking machine to shine the alloy wheels on the trailer behind his Iveco.

It’s called a Rim Shine machine and has three rotating arms with soft pads on them. They fit inside of the alloy wheel rims on a truck or trailer. After putting some polish on them, you roll the machine inside the rim and turn it on, it spins and gives them a brilliant shine, without having to do it by hand, using polishing rags.

Talking of shiny things, I hope many of you Little Trucker readers get to the TMC Trucking Industry Show, being held at the Canterbury Park Showgrounds in Christchurch on 25 and 26 November.

There will be hundreds of trucks to gush over and heaps of other trucking-related activities. I look forward to seeing you there!