Cruising the Coast

Hey Little Truckers, I hope your holidays were awesome. I went on a top-notch trip with Dad for a fairly usual run down to Ashburton, and back north via the East Coast of the South Island.

I woke up for an early 3am start in the April holidays, ready to head away on my next adventure with Dad. Pulling away from Motueka at 4:10am, Dad and I were headed straight down the West Coast to Ashburton. With the music playing and the promise of coffee at Culverden, we set off.

This was the first overnight trip I had gone on with Dad in a very long time, and this journey was extra cool as we were going to be staying overnight in Kaikōura, which is a town I had never visited before. While I fought the fatigue of the early morning (and failed, having a small nap), we made the four and three-quarter hour journey to Culverden. The coffee hit the spot during Dad’s half-hour break, then we continued towards Ashburton, located an hour south of Christchurch. This town is home to Enerpro Feeds, the depot where we were picking up a load of stock feed. Once we arrived and due to the help of a trusty front-end loader, loading took us no time at all and we headed off again.

This load was destined for a dairy farm in Wairau Valley. Our best route to arrive at this farm involved travelling north up SH1, through to the small coastal township of Kaikōura. This made for a beautiful scenic drive, once again reminding me of the amazing views found in the South Island. Travelling through rolling hills and winding valleys, including two road tunnels, the drive soon led us out onto the East Coast, revealing amazing coastal ocean views and a breathtaking sunset.

This truck trip also provided an opportunity for me to see the roading infrastructure that has been placed along the Kaikōura coastline since the events of the devastating 7.8 magnitude Kaikōura earthquake in 2016. The earthquake caused widespread damage across SH1, including landslides. An example of this new preventative infrastructure included sizable metal netting, supported by large steel rods and cables that are engineered to prevent rockfall and landslides (often caused by heavy rainfall) from blocking the road. We then arrived in the township of Kaikōura where we stayed at the Lobster Inn.

It was another early start the next morning where we continued down SH1 towards Wairau Valley. Firstly, we stopped at Riverlands to get fuel. While there I saw some awesome Scanias parked up and captured some pictures. We made great time while watching an amazing sunrise that had begun as we departed. As the sun continued to rise all the way through to Blenheim, it lit remarkable views of the abundant vineyards that are famous in the region. Dad made sure to pull over so I could grab some pictures to commemorate our journey.

The farm is located approximately 30km out of Blenheim and we pulled into the dairy farm right on time for 7am. We unloaded the stock feed, ready for the usual battalion of hungry livestock. I jumped out of the truck to get some pictures of it unloading. We then continued on towards Kawatiri Junction where Dad was dropping me off to get picked up by Mum (about an hour and a half away from home). It was an awesome adventure, staying in a new town, with some amazing scenic views and a great opportunity to spend some time with Dad.

Feed the people

It was an early start for me these summer holidays as I headed out one morning on a trucking adventure to find out about the essential job of delivering groceries.

It was well before dawn recently when my alarm went off to wake me up for my next transport adventure. On a trip to the North Island during the summer holidays, John Baillie, an owner-operator for Foodstuffs North Island Limited, invited me to experience a day in his life behind the wheel.

It was well before dawn recently when my alarm went off to wake me up for my next transport adventure. On a trip to the North Island during the summer holidays, John Baillie, an owner-operator for Foodstuffs North Island Limited, invited me to experience a day in his life behind the wheel.

John operates a Volvo FM 460 tractor unit and it tows a 14.1-metre Fairfax refrigerated trailer fitted with a Thermo King refrigerator unit. The trailer can hold 24 standard pallets on the deck, and in some circumstances, the pallets can be doubled up (stacked on top of each other), which allows more to fit. A rear steering axle is fitted to the trailer that helps it manoeuvre through the tight turns often encountered in supermarket car parks.

John is responsible for delivering chilled and frozen food to supermarkets in the Waikato region. We arrived at the Foodstuffs distribution centre in Manukau City at 2am. This is where the truck is based, and where we would be loading our first batch of chilled and frozen food products for the day.

Upon entering the loadout area at the distribution centre the lower temperature inside was very noticeable, with it being consistently kept at +2 degrees Celsius; this is how frozen and refrigerated products are kept fresh before they arrive at supermarkets.

The first part of the load consisted of frozen dairy products and seafood items such as prawns, along with chilled products that needed to be refrigerated such as milk, sour cream and custard.

John scanned each pallet to ensure they were destined for the right place, before using an electric pallet trolley to load these goods onto the trailer, which made the loading process quick.

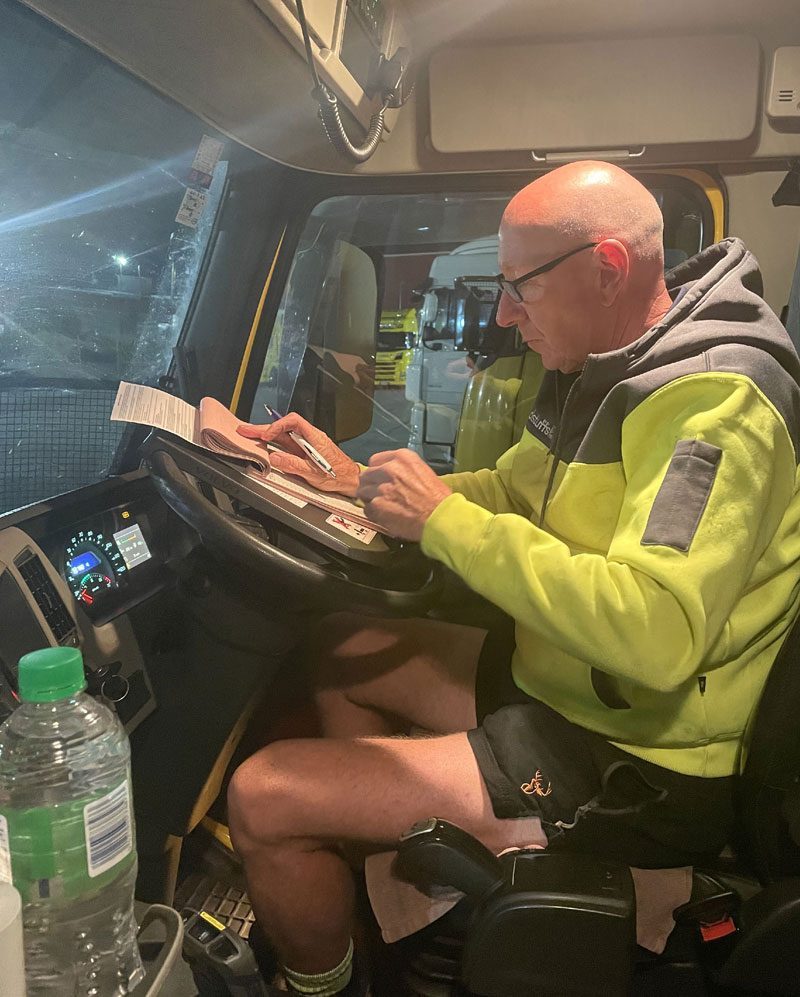

We collected our paperwork from the office and left the chilly building before climbing into the nice warm cab of the Volvo, to first complete the quintessential truck driver task of completing the paperwork.

Leaving Manukau, we headed for a second Foodstuffs distribution centre in Māngere. This time we were set to pick up fresh fruit and vegetables.

While we drove, John updated me on where we would be delivering the groceries to today: New World supermarkets in both Matamata and Cambridge.

As John loaded the fruit, he made sure to arrange the food products in the order of what would be removed first, while also factoring in the frozen aspect.

Working at lightning speed, John made the puzzle of arranging the load in the correct order easy.

On the way to Matamata, John told me about why the grocery runs are completed so early in the morning; it’s mainly due to the traffic that ensues throughout the North Island motorways each day and slows everything down, but it is also about getting the groceries into the supermarkets ready for the shops to open.

When we arrived at the Matamata New World, John cracked open the front doors of the trailer body to get into the front frozen section. Crisp air that had been keeping the frozen section of the trailer at -20 degrees Celsius blew out of the trailer.

The pallets of food were unloaded via forklift and then placed inside the warehouse area of the supermarket. After finishing unloading at Matamata we were back on the road, destined for our last delivery at New World in Cambridge. When we arrived, the same unloading process of last time began, but this time I jumped up in the trailer body with John and helped him move the pallets forward by using the pallet trolley, (this was harder than it looked and I gained a new understanding of the skills required for delivery people everywhere).

I enjoyed my time with John and appreciate even further how vital these refrigerated units are to our city and town infrastructure, and that they are essential to feeding our nation. Next time you go to the supermarket, spare a thought for the men and women working around the clock to keep the food on the shelves that feeds you.

Across the Alps

Hey guys. Come join me on a ride with Steve Richards, a contractor for food producer Goodman Fielder. We went on a trip from Christchurch, over the Southern Alps, to Greymouth.

We met Steve and his Scania R650, paint- ed in the blue and white Molenberg bread colours, in the Christchurch suburb of Harewood.

Steve explained the refrigerated bodies on both the truck and trailer were loaded with a variety of bread, milk and other food products destined for Greymouth, and a few other destinations on the way.

If the truck and trailer were fully loaded with just crates of bread, it would hold around 16200 loaves, that’s a lot of sandwiches!

I climbed into the leather, air-suspended, very comfortable passenger’s seat and checked out the inside of the Scania’s cab, which has a TV, microwave, neat overhead storage cupboards at the back of the cab and a very cool Scania sign on the back wall that lights up.

We rolled out of the city and up Old West Coast Road before joining State Highway 73 (the main road to the West Coast) at the small settlement of Waddington.

Porter’s Pass is the first major hill on the road through the Southern Alps, Steve explained that the weather through the Alps can change in condition from sunny and warm to snowing and cold very quickly.

A set of special chains, which can be fitted to the Scania’s rear tyres are carried in one of the toolboxes, if the truck encounters snow or ice, these can be fitted, to allow the truck to travel safely.

He said I could have a go at putting one of the tyre chains on once we arrived in Greymouth.

Our first delivery was at the Wilderness Lodge between Cass and the Arthur’s Pass Village, where we were met by Mike and his daughters Jean and Olive, who come down to see Steve with their Dad each time he delivers there.

We took some photographs and I gave the girls a copy of the latest issue of Little Trucker Down Under before saying our farewells.

A little further along State Highway 73 is the Bealey Hotel; we had a brief stop here and I was able to admire the large ornamental moa sculpture in the carpark.

Arthur’s Pass Village was our next delivery stop. We unhooked the trailer opposite the railway station and headed down to the café, where Steve drove the truck around the building and reversed towards the delivery entrance.

Some crates of bread were unloaded here and while we were doing this, a few of the noisy ‘locals’ came to see what was happening – and not the humankind.

Arthur’s Pass is famous for the beautiful – but very mischievous – keas, the native parrot of Aotearoa.

The birds are notorious for their knack of stealing things; car keys, wallets, food drinks and sunglasses are common items of interest to the light-beaked, New Zealand native birds.

With the trailer re-connected it was back on the road, we climbed to the top of Arthur’s Pass, the highest point on State Highway 73, and I saw the remains of some snow that had fallen earlier in the week.

It’s all downhill from there. We went down what is known as ‘Peg Leg’, a very steep piece of road that leads onto the well-known Otira Viaduct, a massive concrete bridge that towers 40 metres above the Otira River.

We drove under a spectacular concrete chute that towers above the road and stops the water from Reid Falls washing the road away, then through the Rock Shelter, another concrete tunnel-like structure that protects passing vehicles from falling rocks.

After spending about 45 minutes cruising west with the Taramakau River at our side, we reached Kumara Junction and turned right towards Greymouth.

Upon arrival at the depot, Steve reversed the Scania into the unloading bay and adjusted a large steel ramp, ensuring a nice fit between the building and the rear of the truck.

Now the real work began. Stacks of bread and pallets with milk and other food products were moved from the truck into the building using a pair of special hand trolleys that looked like very hard work.

A team of people would arrive soon after we left to sort and package the various products into orders, which would then be delivered to the supermarkets, stores and cafés by a fleet of smaller trucks.

Outside the depot Steve got a set of snow chains out of the toolbox and explained how they are fitted to the truck wheels. He handed me a pair of gloves and I had a go at fitting them to the tyres. This was quite awkward, but with a little bit of help from Steve, I got them on. It was great to have a go at something a little different.

We put the chains away and I said goodbye to Steve and his very cool Scania. Dad picked me up and we travelled back across the Southern Alps towards Christchurch, and I was able to take some video of the Scania among the West Coast scenery. I will share this to the New Zealand Trucking Media YouTube page so you can all enjoy it.

This will be my last issue before Christmas and the end of the year, so I wish everybody a Merry Christmas and a Happy New Year with your family and friends!

Container Cartin

Motueka has been called “The Fruit Garden of New Zealand” due to the expanse of orchards filled with apples, kiwifruit and hops. I spent some time with Min Wells, who carts containers of fruit from where it is grown and packed to the port at Nelson.

I met Min at a local packhouse in my hometown of Motueka. She drives a Kenworth T410, which tows a Fruehauf quad (four) axle skeletal trailer for AC Palmer & Sons Limited. Some of you guys may remember Min’s truck being on the cover of Little Trucker Down Under’s first issue back in 2021.

We climbed in the Kenworth, which had a 40-foot container on the trailer loaded with cartons of locally grown apples destined for a country on the other side of the world.

As we made our way along State Highway 60 past the Motueka estuary and up onto the Ruby Bay bypass, Min told me that both fruit and wine is being exported to far flung places by ship; this is the main cargo she carts.

We chatted away as we drove through Richmond and around Rocks Road to Port Nelson and I thought the 12-speed AMT transmission made the stop-start motoring through Nelson’s traffic very easy.

I have been to Port Nelson a few times with Dad, and because you must be over 16 years of age to enter the site, I waited outside the gate and watched the endless stream of trucks coming to the port with containers, timber, and logs.

Fortunately, Min explained exactly what went on inside the Port.

After entering the port and driving through to the transfer area, the full container is lifted off Min’s trailer by a large Hyster (container lifter) which has an attachment that hooks into the top of the container.

It is then stacked in a row with other containers waiting to go on the ship, and if required, hooked up to electricity, which is to power the refrigeration equipment responsible for keeping the fruit fresh inside the container.

An empty container is put back on the trailer and secured to it by ISO twist locks, or container locks as they are sometimes called, basically very strong metal pins which have a handle you turn to lock them in place. It means the container is not able to move off the trailer. With an empty container secure on the trailer behind us, we retraced our earlier steps back to Motueka where Min reversed into a specially constructed pit in the ground called a dock.

Once the container’s rear doors had been opened, a steel ramp was put in the gap between it and the floor of the packhouse so the forklifts could bring the pallets of fruit from inside the cool rooms straight into the container.

It took very little time for two forklifts working together to fill the container with pallets neatly stacked with cartons of apples. Once the container doors had been closed, a steel locking tag was put through the door handle to secure it which is equipped with an identification number used by the importers receiving the container.

We hopped back in the Kenworth and travelled the 45-minute trip back to Port Nelson. I said farewell to Min, who headed through the port gates to repeat the unloading process.

I’ve seen so many trucks around the Nelson area carrying containers and it was great to see what they do first-hand. Thank you to Min and AC Palmer & Sons Ltd for having me along.

Down the Coast

Hey Little Truckers, recently I joined Dad on a trip to the West Coast from Motueka to deliver some dolomite (a type of fertiliser used to keep the soil healthy) to a farm north of Westport.

We rolled out of Motueka shortly after 5am and headed down the Motueka Valley towards State Highway 6 at Kohatu in darkness.

As we crested the Hope Saddle, I was treated to a spectacular sun rise, which we managed to get a photograph of, out the rear-view mirror.

In Murchison, Dad topped the truck up with fuel and I was dispatched down the road to get us a hot drink each from the tea rooms.

When I arrived back a Centaland DAF CF was also at the service station, and we followed him south to O’Sullivans Bridge where the road to the West Coast begins.

The Buller River was at our side as we travelled through the Upper and Lower Buller Gorges towards Westport.

Once through Westport, it was onto Waimangaroa (a small town about 16 kilometres north) where we turned down a side road just north of the town.

We met the farmer who was getting our load and he led us to his fertiliser bin where the trailer load was tipped off.

After unhooking the trailer, we took the truck load to a different bin a couple of kilometres further north of the first one.

When we returned to hook up the trailer, with Dad’s help I hooked up the air, electric and hydraulic lines making sure everything was connected properly before we drove off.

Reefton was our next stop, both bins were given a hose out to ensure they were clean before we pulled up alongside the loader.

Just over 38 tons of coal was loaded, we drove across the weighbridge to check the load weight was correct before having our half-hour break.

Once all the paperwork was sorted, we re-traced our steps back up the Upper Buller Gorge and onto Murchison, over the Hope Saddle and along the Motueka Valley to home.

Technology is moo-ving us forward!

Hey, Little Truckers! For this trip with Dad, I was able to learn all about how advances in technology are making a difference in the transport and agricultural industries.

I hope your Christmas and New Year went well and you are enjoying your school holidays. The holidays for me mean plenty of time to head out with Dad. I got to do just that as I went and visited a very cool dairy farm in Golden Bay.

We left home in the Scania with a load of dairy meal pallets (breakfast cereal for cows), which Dad had bought up from Ashburton the day prior and travelled ‘over-the-hill’ to Upper Takaka.

A farm there was the day’s first delivery; Dad backed the trailer up to the famer’s auger, (a long steel tube with a spiral inside it, which is turned either by an electric motor or by a tractor) and once the tractor was started up, the meal began to flow out the small door at the rear of the trailer.

I operated the trailer tipping controls each time the bin needed lifting, and when the bin was right up in the air and the meal stopped flowing, Dad climbed into the bin and coaxed the last of the stock food out with a shovel.

Once the trailer was empty, we left Upper Takaka and travelled about 10 minutes towards the Takaka township, until we reached Uruwhenua Farms, operated by the Sowman family.

Dad unhooked the trailer and backed the truck up to the Sowman’s auger, while he was augering the load, I looked at some cows in a nearby paddock that had interesting collars around their necks.

Corrigan Sowman came over to see how we were getting on and I asked him about the collars the cows were wearing.

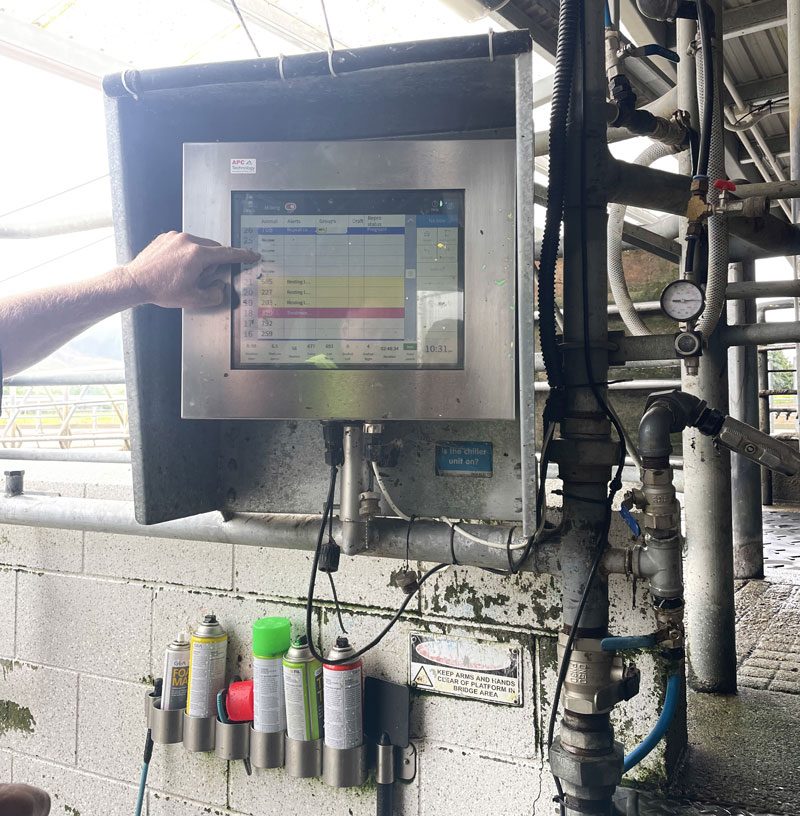

He explained to me that every cow wears an electronic collar that is basically like a Fitbit (or smart watch) for cows. It measures their activities, what goes on inside their stomachs, how often they ruminate (how cows digest food – did you know that cows have four stomachs?), any animal health issues that may be happening for them, and what percentage of the day the cow eats and rests. These are all very important details for a dairy farm owner to know: with this system Corrigan is able to see if there is potential illness or irregularities within his herd, he can then deal with it immediately.

Prioritising the health of their animals and trying to produce a consistent quality of milk is very important to dairy farmers .

The information the collars supply is transmitted wirelessly to the milking shed and it can be viewed either on a computer or smartphone.

Through this technology, if a cow had nutritional issues, the automatic feeders would know what to feed her, how much to feed her and ensure this food only went to her.

Corrigan then led us into his office to show us how he keeps informed of the progress on his farm and how he allocates jobs. He uses an online programme where important information, notes and instructions are imputed.

Corrigan then showed me how to draw a map of a fence where he wanted it set up then it was sent off as a job to one of his employees, through the smartphone app.

The use of innovative technology has revolutionised Corrigan’s farm and also shows just how quickly the world of agriculture is advancing due to new technology and just how helpful it is.

On the way back to Motueka, Dad and I discussed the way technology has made Corrigan’s farming so efficient and allowed him to be able to care for and monitor his cows in the best possible way. This led us to talk about how technology has advanced effectively also for trucks. For example, his Scania truck uses adaptive cruise control, where the truck’s onboard system not only keeps the truck going at a set speed, but monitors any vehicle ahead, and automatically slows the truck down if the vehicle brakes for any reason, making any travel safer for both the truck driver and other road users.

Dad has a tablet for work. It has the loads he is doing on it and as they are picked up and delivered the tablet is updated, in turn sending the completed details straight back to the transport office’s computer.

Technology is enhancing all industries, including transport and farming. For people like Corrigan and Dad, they appreciate the difference these technologies make to their jobs and they can’t wait to see what comes next.

Truck show time!

The Historic Transport Museum Trust is a group of people dedicated to preserving transport history in the upper South Island. They hold a show each year and in early October I went out to Pigeon Valley, south of Nelson, to have a look at this year’s event.

When Dad and I arrived, the event was already in full swing and the grounds were full of trucks.

We made our way around the grounds and there was much to look at. Trucks of all different shapes and sizes, old and new, scrubbed clean and ready to be viewed.

Many local transport companies had put in an amazing effort to get their vehicles looking their best for the show.

Some trucks that really stood out to me were three stunning Kenworth Aerodynes, belonging to Austin Transport Services, that were polished to perfection.

Four heavy tow trucks were lined up down the back of the grounds. It was neat to be able to get up close to them and Dad explained how they recover trucks that get stuck or have broken down.

We also spotted a big red truck that looked quite old-fashioned. I asked Dad about it and discovered it was the first ever Hino to come to New Zealand, brought here from Japan, all the way back in 1960.

Later on in the day, we came to my favourite part of the show, the truck pull! Teams of three people from different transport companies competed to see who could pull a truck along a short road, in the fastest time.

I watched some epic pulls by teams from the local companies and organisations (even the New Zealand Army soldiers, who had brought their military truck to the show, joined in).

The winning team only took 17 seconds. As we made our way out of the grounds, I farewelled the awesome show. The Pigeon Valley Truck Show was not one to miss!

By the time you guys read this, the holiday season won’t be very far away. Have a good time with your friends and family. I plan to get out in a couple of trucks over the school holidays and I will tell you all about it next time.

Happy holidays,

Milly

Wash time

With trucks all over New Zealand taking a battering from winter weather conditions, keeping your truck clean is important, not only because it looks nice and positively represents the industry, but also it can make spotting any maintenance issues easier than if it’s plastered in mud, dirt and grime.

Hi Little Truckers, I hope everybody is well and you are all keeping warm over winter. I have had a busy few months and there has been no opportunity to do a truck trip with Dad unfortunately.

However, I jumped at the chance to head over to Sollys Richmond Depot recently to meet up with Dad and help him wash the winter’s grime off the Scania.

Mum drove me across to Richmond, I caught up with Dad and after being shown the controls and what to do I was able to drive the Scania onto the wash pad…..what a thrill!

We wet the truck down, then sprayed it with detergent from the foam gun, before sponging the cab and wheels and scrubbing the rest of the unit with a soft brush.

Dad and I then had ‘turn-about’ using the water blaster to clean off the loosened dirt. As we worked our way around the truck and trailer, I asked Dad if he liked washing his truck.

“It’s certainly not my favourite part of the job but I like the finished result,” he said.

I think he secretly hopes I will offer to clean it each week!

We left the Scania to dry in the sun and headed to the smoko room where Dad said he ‘would shout me a cup of tea’ for helping with the washing.

On our way across the yard, I saw Leighton using an interesting-looking machine to shine the alloy wheels on the trailer behind his Iveco.

It’s called a Rim Shine machine and has three rotating arms with soft pads on them. They fit inside of the alloy wheel rims on a truck or trailer. After putting some polish on them, you roll the machine inside the rim and turn it on, it spins and gives them a brilliant shine, without having to do it by hand, using polishing rags.

Talking of shiny things, I hope many of you Little Trucker readers get to the TMC Trucking Industry Show, being held at the Canterbury Park Showgrounds in Christchurch on 25 and 26 November.

There will be hundreds of trucks to gush over and heaps of other trucking-related activities. I look forward to seeing you there!

Heavy Haulin

Hey Little Truckers, I hope everyone is well and has seen some cool trucks out and about. Recently, I had the chance to learn all about heavy haulage, and how over dimensional (high, wide, and heavy) loads are moved.

On a cool morning in April, Dad and I drove down to Reefton on the South Island’s West Coast, to meet up with Daniel McKenzie from Satherley Transport, who took me on a rather exciting trip.

Parked on Broadway (Reefton’s main street), was a stunning Kenworth T909 with a massive load on, a Hitachi EX1200 excavator weighing around 65 tonne.

We had a walk around the Kenworth. It has a 615hp Cummins Signature engine and was towing a two-rows-of-eight load divider and a four-rows-of-eight trailer. Let me explain a little more. Firstly, a loaddivider is a small trailer between the prime-mover (truck), and main trailer. Its job is to take some of the weight off the primer-mover and prevent overloading. Also, when we’re talking about heavy transporters like this one, we say ‘rows’ rather than axles. The reason is, there are no axles that run right across like a normal highway trailer, instead the wheels are in four groups of two across the width of the trailer – that’s why we say ‘eight’ (4×2=8). There are two groups at the outside, and two either side of centre. They are built like this so there are more wheels and tyres to carry the load. In total, we had 58 tyres on the road!

This colossal load was destined for the Stockton coal mine, north of Westport and I was lucky enough to be invited to come for the trip.

The excavator was so large that the cab, arm, and bucket had to be removed from it and was taken to Stockton the previous day on another truck.

Satherley Transport are a New Zealand-wide heavy haulage company. Their big blue Kenworths can be seen all over the country with some pretty cool loads on.

I climbed into the cab with Daniel and we headed off. Two pilot utes travelled in front of us, warning road users that a large vehicle was approaching, and they also let Daniel know of other hazards.

Many oversize load moves take place in the early hours of the morning to avoid traffic, however, this load was able to be done in the daytime, which was a special treat for all passersby to see.

The most direct way from Reefton to Stockton is via Inangahua Junction and the Lower Buller Gorge, however the load was too big to travel on that route.

Instead it was south over the Reefton Saddle (a big hill!) and down the Grey Valley. Daniel skilfully manoeuvred the load over the very narrow Mawheraiti Bridge, and we drove through the Grey Valley to Nelson Creek.

Here we turned left and travelled inland through Deep Creek, re-joining State Highway 7 at Stillwater just North of Greymouth.

From here it was across the Grey River and through Taylorville where we turned right onto State Highway 6 toward the coal town of Runanga.

Daniel has hauled many different loads in his time working for Satherley Transport, including different types of construction, forestry, and mining equipment.

He showed me a folder that had permits in it. They showed where the truck is able to travel and how much weight can be carried on certain roads. The permits also detail where the bridges are enroute and what instructions need to be followed when crossing a particular bridge with an oversized load.

I asked Daniel how heavy the truck, load divider, and trailer plus the excavator would weigh added together, he said “around 100 tonnes.”

North of Runanga State Highway 6 follows the coastline for much of the way towards Westport. At a place known as ‘the Ten-Mile’, Daniel executed a three-point-turn and crossed a bridge. I looked out the mirror and had an amazing view of the excavator from behind as it came across the bridge.

The sky darkened and a light drizzle started north of Punakaiki where the famous Pancake Rocks are, however this didn’t cause us any issues and the Kenworth with its big Cummins engine made easy work of the job.

As we got closer to Westport there was a lot more traffic around. We crossed the Buller River and turned into Mill Street. Unfortunately, after a fascinating day I had to say goodbye to Daniel.

Dad picked me up and we drove 25 minutes north to Granity where the Stockton mine turn-off is. We parked the car and patiently waited for Daniel at what is known as ‘The Grand Canyon’, a really steep section of the road into the mine. To help Daniel and the Kenworth get the load up the grade, Jared Avery from local Westport company Avery Brothers hooked his Hino tipper on the front.

The flashing of pilot vehicle lights came into sight, and we saw Jared, then Daniel. Working together they steadily climbed the incredibly steep mine access road.

We watched the excavator disappear through the gates into its new home at the mine where it will be put back together before going to work.

Just another day for a heavy haulage truck driver, but a lasting memory for a truck and heavy machinery enthusiast.

Trip to Golden Bay

Hey Little Truckers, I hope you have all had a great Christmas and New Year! I have been quite busy these holidays but I still managed to fit a really cool trip in.

On Christmas Eve 2021, I jumped in the cab with Dad, and we made our way over to Takaka, Golden Bay to complete a delivery and load up. We headed off at 6am on a journey of just over an hour, made a bit quicker than last time as the roadworks on the Takaka Hill had finally been completed after damage from Cyclone Gita in 2017.

We made it to the Sollys Depot on Commercial Street where we tipped the trailer load of palm kernel off in the bulk store.

We unhooked the trailer and went to a farm at Hamama. When we arrived, we started to unload the truck load of palm kernel. Palm kernel is popularly used as stock food for cattle. I had the pleasure of meeting a very friendly calf there, who came over to say hello, while Dad worked on unloading.

He tipped half the load off before jumping out and borrowing the farmer’s tractor, to push the kernel up into the back of the shed. He was then able to tip off the other half of the load. He did this because the shed was too low to tip straight into and tipping it off altogether would result in a big mess, leaving the kernel out in the weather! This is a practice for many truck drivers, with some customers often leaving their tractors, forklifts, and loaders nearby for them to use. Drivers being able to drive tractors, forklifts and loaders are skills that many drivers learn early in their career.

I farewelled the calf and we made a quick trip back to Sollys depot to hook up the trailer. Shortly after we bounced on up to the Golden Bay Dolomite plant located at Mount Burnet at the northwest corner of the South Island. The views out to the Tasman Sea and along the coastline, from the deck of the site office there, are beautiful. While I was playing photographer and catching some action photos, Dad got on the loader and packed the bins full of dolomite. This load was headed for Canterbury, between Christmas and New Year. Before heading back over the Takaka Hill with its 360° corners, we stopped back at the Sollys depot for a drink, something off the barbeque, and a catch-up with some of the drivers who were enjoying the staff Christmas Eve shout. We made it back home to Motueka for lunch with the family eagerly awaiting Christmas the next day. All in all, this short half- day trip was efficient and accomplished all that was needed, while affording me a meeting with a very cool furry friend.

I look forward to the next trip!