Winter safety

Truck drivers need to be careful on the roads all time of year. But the winter season brings rain, hail, snow, ice and slippery roads. Truck drivers are experts when it comes to safety, and it is necessary to adapt how they operate their truck when driving in poor weather conditions, especially on snow-covered or icy roads.

BLACK ICE

Black ice is a thin layer of transparent ice that forms when the temperature is close to freezing. Truck drivers look for ice build up on their windshield, and slow down when approaching shaded areas, bridges and overpasses as these sections of road freeze sooner than others in cold weather.

PLAN AHEAD

Professional truck drivers plan their journey. They will check traffic updates and weather forecasts, and think about what route is best to take to ensure they get to their destination safely. If the weather is bad, truck drivers will allow for extra time and drive in daylight hours when visibility is better and ice is less likely to be on the road.

DROPPING SPEED

Truck drivers will drop their speed to match road conditions. No matter how much experience a truck driver may have, the way their truck will move on snow or ice can be unpredictable.

PACK THE RIGHT STUFF

Truck drivers will dress for the conditions, so if it’s cold they will wear and bring with them warm clothes and appropriate footwear. They’ll also have a survival kit in the truck in case they get stuck.

Create a truck enter our mini big rigs competition!

Calling all budding model truck builders! Do you think you have what it takes to build your very own mini truck model, using household items? Enter the competition below and you could win some very cool prizes!

Do you think you could create your own truck model?

Have a go at creating your very own truck model and you’ll go in the draw to win some very cool prizes! Use any household items you can find, like cardboard boxes, plastic bottles, wood, containers, duct tape… anything you can think of! It can be built in any scale, and also be completely imaginary with regard to axle/wheel combinations, so let your mind loose! There will also be extra points for the livery design and colour scheme you choose to adorn your rig with.

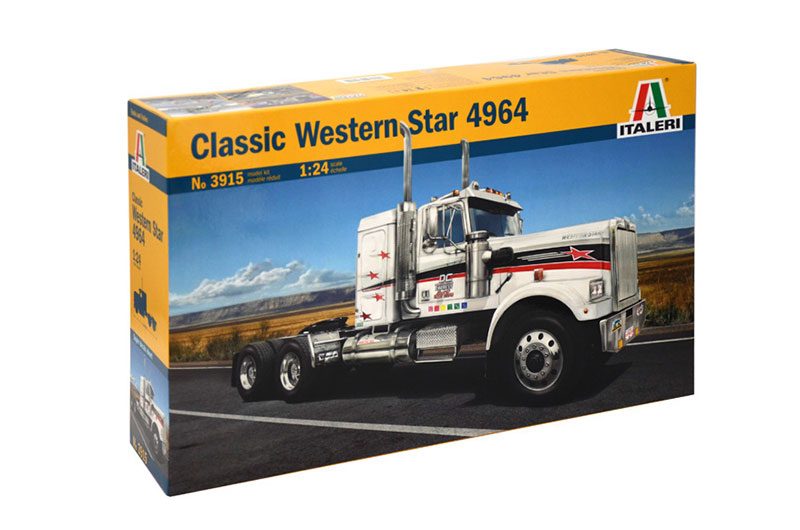

Our friends at Italeri have very kindly provided three prizes for three separate age groups. The competition closes at midday on Monday 7 November, so you have heaps of time to get creating!

The competition will be run in three categories – up to the age of 7 years, 7 to 14 years, and 14 years and over. The prizes for each of the three age groups will consist of an Italeri kitset model truck and either a New Zealand Trucking or Little Trucker Down Under cap. Pretty cool prizes to work for and plenty of time to get building, so do not hold back and get into it now!

Send photos of your build and builder information to carl@nztrucking.co.nz before the competition cutoff to validate your entry… Happy building, we can’t wait to see what you come up with!

Graeme Wright General Carriers

Milly McCauley has spent plenty of time in the passenger’s seat of trucks involved in rural cartage. In this issue of Little Trucker Down Under, she heads north to Puriri, a wee village in the Thames Valley, and chats with local trucking identity, Graeme Wright.

Who owns Graeme Wright General Carriers?

Graeme: The transport company is owned by me, Graeme Wright, although everyone knows me as ‘Gunner’.

How long has Graeme Wright General Carriers been in business?

Graeme: I’ve been in business since 1969, over 50 years now.

Where do you have trucks based?

Graeme: The main depot is here in Puriri, however some drivers do park their trucks at home in nearby towns.

How many trucks does Graeme Wright General Carriers operate?

Graeme: I have 20 trucks. A large amount of the company’s work is seasonal, so although not all of them work at the same time necessarily, we still need trucks ready for any service we may need to provide.

How many people does Graeme Wright General Carriers employ?

Graeme: The transport company has around 20 employees including drivers, workshop, and office staff.

What type of loads do you cart?

Graeme: Being rural carriers, it’s largely the farmers’ needs. This includes livestock, fertiliser, stockfeed, metal, farming equipment, and the occasional timber loads.

Where are the main areas you operate in around New Zealand?

Graeme: Aside from the Thames Valley and Coromandel Peninsula, we also cover much of the North Island when we need to, like the large cattle moves to Kaitaia yearly – helping cart over 2000 cattle.

What is your title at Graeme Wright General Carriers, and what are your responsibilities?

Graeme: Well, I’m the boss. I oversee everything, and help to keep the peace!

Did you always think you would work in transport?

Graeme: I have loved trucks since the day I was born. I still do. I was brought up around trucks and the rural environment. It was always going to be a career in transport.

What is the best truck in your fleet?

Graeme: Hmmm. The best truck I have ever owned, which is not the same as my favourite, is a Volvo FH520, which has done over 2 million kilometres, and still works around the Thames Valley and Coromandel every day.

Can you tell me a fun or interesting fact about Graeme Wright General Carriers?

Graeme: Graeme Wright General Carriers has managed to succeed in a small rural area and operate for many years. I’m really proud that I’ve been able to fulfill my dream.

What would be some advice you would give to any young people who want to start a career in transport?

Graeme: Look for opportunities and find your break and make connections with others. Those connections will last forever and help you get to wherever you want to go.

What makes of trucks do you have and how many of each?

Graeme: I guess you could say the fleet is a bit of a ‘fruit salad’. Kenworth, Mack, Volvo, Scania, Hino, Mercedes-Benz, and Iveco are all represented.

What’s your favourite thing about working in the industry?

Graeme: Nothing beats the trucks themselves.

Learning on the job

We meet Madyzin Rogers and Jason Andrews, two young heavy fabrication apprentices at Rotorua trailer builder Mills-Tui.

As heavy fabrication apprentices, Madyzin and Jason both learn to work with metal in the construction of trailers. This includes measuring, cutting and folding various types of sheets of steel. They also weld them to form the various components that are assembled to make a trailer.

The apprenticeships consist of about 50% on-the-job work, and 50% bookwork. So you have to be dedicated and motivated to get through it all.

However, if you do, there’s a wide variety of jobs you could choose from – the whole world is hungry for tradesmen! Trailer building is quite a niche specialisation, so you should always be able to find a job. You could even land up running your own company!

How long are your apprenticeships and which training organisations are you doing it through?

M: We both do our apprenticeships through Competenz.

J: They should take three to four years to complete.

What’s the most fun part of your job?

M: Standing back and looking at the finished product, knowing I helped build it.

J: Pressing the material with the hydraulic press.

What’s the toughest part of your job?

M: Sitting down at the end of a long day to do the bookwork.

J: Yeah, I agree!

Did you have to do any specific subjects at school for your apprenticeship?

M: I left school at 16 to join Mills-Tui. I wanted to work.

J: No, but I’d say the subjects I did at school have helped – I did maths, carpentry, engineering, science, that sort of stuff, which is all pretty relevant. Otherwise you might need the right tutors to teach you.

If you didn’t enter engineering, what would you have liked to do?

M: I always wanted to be a truck driver!

J: I tried building, bricklaying and sawmilling, but it was always engineering for me!

Loading up the truck

Reid heads out to do some earthworks with his stepdad, Ben. He saw tractors, diggers, rollers and loaders, all from a Kenworth.

Name: Reid

Age: 9

Can be found in a: Kenworth

My step dad Ben works at HDL, which stands for Hill Development Limited. They do earthworks for subdivisions. One Saturday my brother Heath, sister Lily and I got to hang out at Ben’s work.

The boss, whose name is Mike, gave us some HDL shirts and a couple of walkie talkies to communicate with.

First, we started up the 2003 T404 Kenworth 6×4 alloy bin tipper with 18-speed road ranger transmission. The C15 550hp Cat engine was super loud and my sister honked the horn, which was even louder! Today’s job was to fill in a hole with sand/ash, so we needed the Komatsu 13-tonne digger to load up the Kenworth truck.

As the digger loaded the truck, I could feel it shaking like a truck rumbling past our house. Then we backed up the truck to the hole and dumped the load by tipping the deck. Second time round I went in the digger with my step dad – it was fun to push the levers and watch the scoop load the truck.

It was cool seeing the other machinery too like tractors, diggers, rollers and loaders. I had an epic day hanging out at Ben’s work site.

A big day out with Pop

Ezra and his brother Kyen love seeing their Pop in his big, turquoise truck.

Name: Ezra

Age: 7

Can be found in a: Mercedes-Benz

Hi my name is Ezra, I am 7 years old and my brother’s name is Kyen, he is 2½ years old.

Over the holidays, my Pop, Wayne, took us for a ride in his truck. My dad, Shane, came too. My Pop’s truck is a Mercedes-Benz, it has 600+ horsepower – wow! The colour of his truck is turquoise.

We drove the truck from the truck yard, over the motorway, and back again to the yard. We saw lots of diggers and other trucks in the yard too. When we were driving in the truck, we waved at the other truck drivers.

I really liked being in my Pop’s truck because you are so high up compared to the cars. The cars look so small. My little brother Kyen made lots of noises in the truck because he was so excited. He loves trucks and enjoys playing with them at home too. It was such a fun day going out on my Pop’s truck and I think he is a great truck driver.

What is Fuel Efficiency?

What is fuel efficiency, and why is it important?

When we talk about fuel efficiency, we are talking about the amount of fuel used per unit distance - for example, how much diesel or petrol does a vehicle use per kilometre travelled?

The transport industry is working hard to operate more efficiently to help the environment, and one of the ways it does this is by using more efficient trucks.

An efficient truck means it is operating or working in a way that gets results, with little wasted effort.

Better fuel efficiency means that for each kilometre travelled, you burn less fuel and release fewer carbon emissions into the environment.

Look at features that help driving more efficiently such as engine, drivetrain and transmission. Other helpful features that reduce weight include alloy wheels (lighter than steel) and low resistance tyres. Air foil and mirrorless cameras that reduce wind resistance can also help saving fuel for truck drivers.

Choosing more fuel-efficient vehicles is one of the most effective ways to reduce greenhouse gas emissions, and lots of truck companies now choose to purchase trucks that are better for the environment.

Restoring a classic truck Part 2

1985 V8 Mack Cruiseliner

Graeme purchased the Mack Cruiseliner in 2006. Although It was looking pretty rough after spending the previous years outside and not in a shed, it was still drivable and Graeme drove it home from Auckland, parked it in his shed where it stayed until 2009.

Graeme tells me this particular Mack Truck is very rare. Another interesting fact is that the purchase price in 1985 was $226,325, back then you could possibly buy 10 houses for the same price!

Before owning this Mack, Graeme owned another years ago and had originally wanted to buy it back, but it was unavailable.

When this one came up for sale, Graeme bought it.

In 2009, Graeme decided it was time to start working on restoring the truck. After sitting for so long untouched, it was not driveable. Luckily, Graeme owns a fleet of trucks (GK Skou Transport Limited) and was able to transport the Mack himself. It was taken to Jackson Enterprises in Paihiatua and dismantling began.

For about a year, most weekends were spent working on the Cruiseliner. Graeme was able to do a lot of the work himself, but he did have some help from James Rook with some of the larger jobs.

Many, many long hours were spent sanding, cleaning and polishing what seemed like endless parts. He managed to keep most of the original parts, with exception of the front seats that were too far gone to be repaired. New seats were sourced from a Hino and Graeme re-covered them in a material of his choice. The headlights are Holden Gemini, but rumour has it the original ones are too. The brakes were done at Rangitikei Truck and Diesel. The chassis was sandblasted and painted red by Total Truck Spray in Palmerston north. The mudflaps are all stainless steel, not chrome. Graeme says this is because they don’t rust and stay shiny longer! The wheels and the chromed grill are all original. The cab was stripped back to metal before getting repainted – the first time in five different paint jobs – and the thickness of the paint they took off reflects this.

The colour scheme is very similar to the original colour of the truck when it was new at Total Transport. This is a coincidence as the colour scheme Graeme chose is that of his existing fleet at GK Transport, which consists of 12 trucks – 8 livestock and 4 tippers. The engine, a E9 V8 440 (uprated to 500 hp) Mack motor, was painted blue. Graeme chose blue because he is sure that is the original colour. Running alongside that is a 12-speed Mack gearbox. Both are the original parts from new.

The gold Bulldog emblem in the steering wheel was custom made and put in two of Total Transport’s Macks when they were built. Pretty cool!

Graeme and his wife Raelene took the Mack for its first run as part of the North Island Northern Classic Commercials. It is a rare occasion that it gets taken out for a drive. They have now been on five runs including both the North and South Islands.

Graeme took the Cruiseliner to the Tui Truck Show and Shine at Mangatinoka in 2011 where it won “Mack of the Show” – this is the one and only show he has attended with this truck.

NOT-SO 'STOCK' UNITS

Perfect replica diecast models of iconic Kiwi nine-axle stock units – who could have thought? This month, we drop in and meet those who did imagine, and have now made them a reality.

For an eternity, diecast model-truck collectors countrywide have dreamt of a manufacturer that could make accurate representations of the typical Kiwi rigs we see on our highways. Well, that wait is over. Our good friends at Model Barn, outside of Thames, have been extremely busy resolving this gap in the market. After many years of research, Model Barn’s director Jeremy Welsh is proud to reveal the company’s pet project is nearing completion.

Arriving at the Orongo Road retail store it’s impossible to miss the pair of FH Volvo Globetrotters sitting proudly in a display cabinet front and centre. We find ourselves staring in awe of the two pre-production blanks. First impressions of the 1:64th-scale Globetrotters are the accuracy of the finer details. At this scale, many manufacturers will skim over the finer points. But it is not the case here. From the spotlights to the signwriting and scrolls, the team has captured the essence of the life-sized rigs from every angle.

Jeremy explains that the vision behind ‘Kiwi Replicas’ was to provide the market with model trucks that accurately depict the unique configurations found in New Zealand. “There are plenty of trucks out there that we get from Australia. They are great; they are right-hand-drive, so they are similar, but the trailers are not the same.

“There are also plenty of trucks available from Europe and America, but they are all left-hand-drive, so I wanted to make something that was uniquely New Zealand. The four-axle truck with five-axle trailer combination that we see here was what I wanted to build.”

The choice to base the first builds on the Volvo Globetrotter was assisted by Jeremy’s project manager, who had worked with Volvo previously on another project. The FH Globetrotter is also a common weapon of choice with many livestock operators, ensuring no shortage of candidates for the future.

The first two cabs off the rank for Kiwi Replicas are ‘Miss Stacey Jade’, an FH750 belonging to the local Thames Valley fleet of Graeme Wright General Carriers in Puriri, and ‘The Swedish Palace’ FH700 of Transport Services Ltd (TSL) from Nightcaps, deep in the south. According to Jeremy, both companies were elated to have their trucks replicated as models, and he is moving forward with plans to build another eight units. He has already approached other well-known liveries to garner their interest, and they are equally as excited, so watch this space.

Out and about with Rossco Bobcats

Kaitlyn met up with our friends over at Rossco Bobcats, and learned all about how quick bobcats are compared to other vehicles. She also got to check out some classic trucks.

Name: Kaitlyn

Name: Kaitlyn

Age: 10

Hails from: Canterbury

Goes to: Shirley Primary School

I recently got the opportunity to go out with my mum to Rossco Bobcats, a Christchurch-based transport company. We got to meet Rossco and his wife Wendy, as well as their mates Shane Pearson and Mark Amer, who everyone calls Magpie.

Rossco has run the company for more than 20 years. On our visit, we got to go in Rossco’s truck, which had a bobcat on the back. It looked amazing.

We also got to go in Magpie’s truck. He took us for a nice ride around Rolleston and told us all about the work he does and how he loves working in the transport sector. Magpie does a lot of travelling and says he really enjoys his job.

Shane took us out in his Kenworth truck. He told me it costs $700 a day in fuel to run a truck! Wow. He starts early and finishes by 4pm, making a full day of it.

Shane showed Mum and I around his big garage, which had a few old fashion trucks in it. I loved the L&P truck. We also saw a lot of trucking memorabilia that was nicely displayed.

I really enjoyed my morning and meeting Rossco and his mates, thank you so much for having me.

Rossco and Wendy Higgins own and operate Rossco Bobcats, a general earthmoving company that works on everything from landscaping, driveways, section clearing, and floor pads for new homes, all around Christchurch and the wider Canterbury region.

After working on a bobcat for his brother-in-law, Rossco decided to branch out on his own, and now has been operating bobcats for 40 years. The company owns three trucks, a skid steer loader, and a 5.5 tonne bobcat excavator.

Rossco says bobcats are very quick and efficient, and faster than other machines.

While Rossco is operating the machines, Wendy takes care of all the bookwork and accounts.

“She’s my rock,” says Rossco. “We’ve built the business up together and are really happy.”