Riding shotgun with Aaron

Rochelle spends a day in the life of a log truck driver

It’s 2am when my alarm goes off. At 4am I meet Aaron De Silva at the Riversdale Beach turnoff, just south of Masterton, an hour’s drive from my house. When I arrive Aaron is doing a check on his truck ensuring everything is in order. He lives in Palmerston North and started work at 1.30am!

Aaron drives a Kenworth K200 for HP Transport, owned by Joe Potter from Trentham. He has been working here for nearly three years but has a driving career of 30!

Once the check is complete, we head off to Blairlogie Forest. We are doing local runs delivering logs to either rail or Kiwi Lumber. This has been Aaron’s daily run for the past two months. It keeps him away from home Monday to Friday, returning home to his family on the weekends.

When I ask Aaron what he loves most about his job, he tells me it’s the scenery. Doing this kind of work takes him to some remote places around the country and he gets to see some beautiful sunrises and views. Unfortunately, it was overcast, and I was not lucky enough to see the sun come up.

When we arrive at the forest to be loaded, we have to pull over up the hill a bit and wait because there are a few trucks ahead of us and it’s a very narrow drive down. We aren’t waiting too long before Aaron gets a call saying another driver is stuck, struggling to get up the hill loaded on the loose gravel. Aaron, being very good at his job, shows off his driving skills by doing a three-point turn on this narrow road and reversing down the winding track in the dark. He makes it look easy but I’m not going to lie, it got my heart racing a little! Once down they hook the other truck up to Aaron’s and he tows him up the hill.

The first thing the loader driver does is lift the trailer off the truck. Log trucks carry their trailers on top of the truck when empty. By 5.30am we are loaded with 6.1m logs that will be used for export timber and head off to Kiwi Lumber in Masterton. Aaron has a forestry app called WSX where he enters where he’s been, where he’s going and what he’s got on. The information is emailed to dispatch. Aaron’s truck has a 48-tonne permit and scales on the trailer that weigh his load to ensure he carries the correct amount of wood. He puts 25 tonne on the truck and 22 tonne on the trailer. The logs can be loaded no higher than the bolsters that support them. The loader driver, James, is an expert and gets the loads bang on! Slow and steady is the drive out of the forest, because the gravel is so loose on the rough road and we don’t want to end up stuck like the truck before us. Aaron also explains to me how easy it is for the trailer to kick out, slide and flip.

Before we unload, we stop at Waingawa weighbridge to record the gross weight (loaded), and then once unloaded we go back to record the tare weight (empty). Here we also pull into the gantry, where a huge hook and chain is used to lift the trailer onto the back of the truck.

At Kiwi Lumber, we must wait our turn to be unloaded. Aaron pulls over and uses this time to undo the chains, catch up with other drivers who are also waiting, and update his logbook. When the loader driver is ready, he calls us in and we park safely in the unloading zone. At this point we are not allowed to leave the vehicle, but they make an exception for me to get photos from a safe distance wearing the safety gear I have been given, a hard hat and hi-vis vest so I can be seen.

Each round trip, loading and unloading, takes about three hours and Aaron does three or four of these each day. I stay on for one more circuit, then Aaron drops me off at my ute and I head home and let him carry on with his day. Driving a log truck takes some skill! Gorgeous scenery and some big challenges are all in a day’s work. Thanks a heap for letting me tag along Aaron, I had a great time!

Riding shotgun with Lucy

Rochelle spends the day with a stock truck driver

At 8am I arrive at the Martinborough Transport yard in Masterton, where I meet 26-year-old Lucy McLennan. Lucy drives the brand-new 2023 Scania R520 XT manual truck and trailer unit. This truck has only been on the road a month and done 9000km.

Lucy’s dad is a truck driver, so she grew up around the industry, but it wasn’t until just two years ago that Lucy decided to go for her Class 2 licence. The instructor referred her to Jared Hawkins and that was the start of her driving career at Martinborough Transport. Before driving trucks, Lucy was a photographer and still enjoys taking photos, but absolutely loves driving. She loves going to the farms, meeting people, building relationships and the challenges of going to remote places around the rural community.

The first place we head to is Bowlands Farm Block #1 out towards Bideford, and along the way Lucy tells me this load of 400 ewes and 200 lambs is the biggest load of sheep she has transported so far. Lucy also explains that she needs to put the heavier stock on the bottom levels of the trailers so it’s not top-heavy and topples over. The rear trailer also needs to be heavier for good traction, so it doesn’t skid or slide.

We arrive at Bowlands around 9am and Lucy backs the unit up to the yards and ramp. The farmer helps guide her in the right direction as it is very important that the trailers are lined up straight, so the lambs don’t fall between the truck and trailer whilst loading and so stock don’t get stuck and hurt themselves.

The trailers have four levels! And each level has little pens so the sheep can be separated so they are not overcrowded and crammed together too tightly. It was so interesting watching Lucy count the ewes and lambs, put gates up, fold floors down and see how so many animals fit onto the truck. It’s very much like a jigsaw puzzle! Each pen holds approximately 8-9 ewes or 18-20 little lambs.

These sheep are just heading up the road on the same farm; the farmer has chosen to transport them via truck and trailer rather than walk them as it’s too far for them to walk. We arrive at Griffin (Pink Crown) Block #2 at 10.45am and Lucy backs up to the yards. The farmer meets us there and we let the ewes and lambs off.

It’s now 11.15am and we head to Martinborough with two stops along the way. First, we went to Baird & Hendersons farm, Gladstone. Here we load 219 sheep. The farmer tells me he is selling them now while the price is good as they were last year’s lambs. If he waits much longer the teeth will come through and then they are classed as mutton and the price drops by half per kilo. When we leave this farm, we drive past Lucy’s cousins’ house. Lucy says a big shout out to Jack, Troy and Graeson McGregor.

Next stop is Hinakura, it’s raining when we arrive to pick up 40 ewes then we head to the Martinborough Transport’s main yard. We arrive at 1.30pm and here in the yards are about 190 sheep that have been collected from various farms around the area in small lots ready to be transported together in the big truck. Jared and his dog Charlie help load these sheep, which are going to AFCO Freezing Works in Whanganui to be processed and then exported overseas as meat to eat. Once loaded we head back to Masterton making one more stop along the way at the old sale yards to pick up 25 more sheep, which then completes Lucy’s load and fills the unit. We get back to the Masterton Martinborough Transport Ltd yard around 4pm and this is where I jump out and head home. Lucy’s day is not over though. She continues trucking up to Whanganui where she will unload and stay the night before reloading and return home tomorrow. It has been an awesome day, thank you for letting me tag along Lucy, I learnt lots!

Riding shotgun with James

Rochelle heads out with James from Croskery Contracting in Masterton to learn all about what a day in the life of a trucker really looks like.

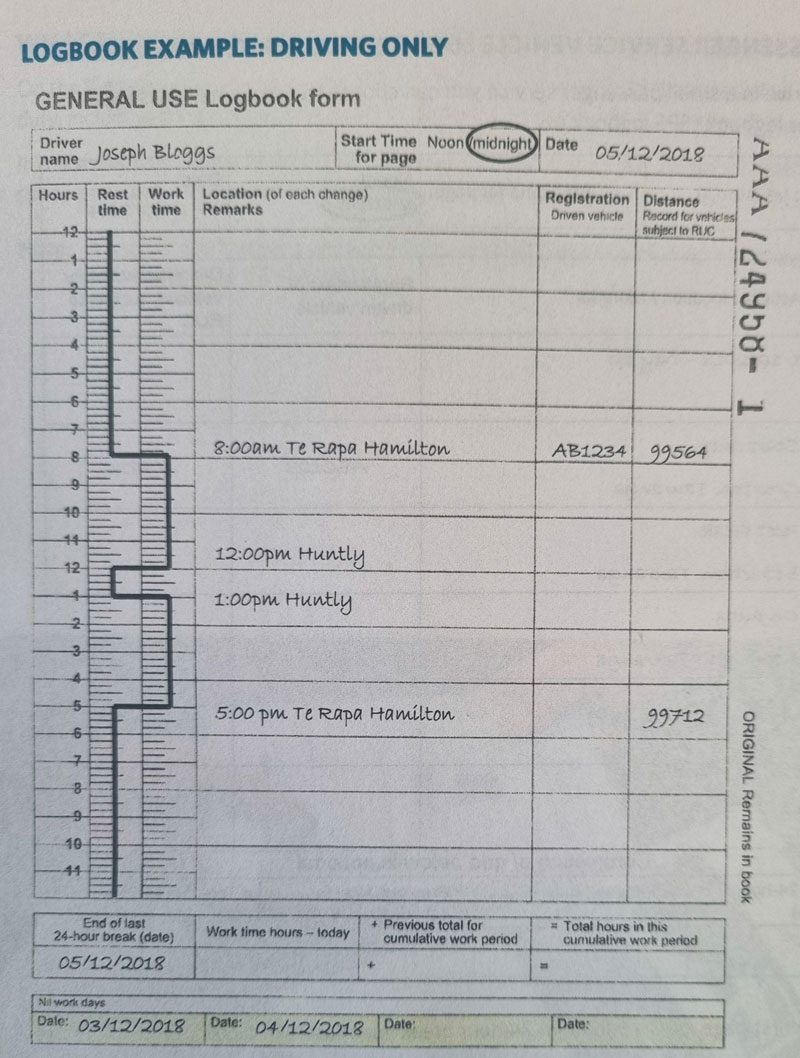

It’s still pitch black when I arrive at the Croskery’s yard before sunrise at 6.30am to meet up with James Sladden. I am given a hi-vis vest and we head to his truck, a 2018 Volvo FM500. The first thing he does is a safety check, walking around the truck checking his tyres. We climb in and while the truck is warming up, James starts his logbook for the day.

We head over to a pile of crushed metal (stones) where James parks the truck and climbs into the loader and loads his truck with 26 tonnes of 65ml metal.

Once loaded we drive two hours to Tora Beach, South Wairarapa. The views are stunning and when we arrive the sun is rising across the bay above the hills – so beautiful, something I don’t get to see every day!

James has been working at Croskery’s for two years, previously he was working at a quarry, Taweru Lime Works, in Masterton for 20 years. He has always loved trucks and as soon as he was old enough, he got his HT licence at 16 years of age. James loves being out and about seeing the country and enjoys the different challenges this kind of work offers.

At Tora Beach the truck was unloaded trailer first onto the muddy gravel road while the truck was driven very slowly forward. A digger followed, spreading the metal. From there we continued down the hill and turned the truck around and headed back up the slippery slope and emptied the truck bin. Then we got stuck! With some clever driving skills and some help from a digger pushing us from behind, we were on our way again very quickly. Our next stop was Peter Warren Aggregates, Featherston. The first thing James did was fill in some paperwork, this is to sign in to say he’s on site. Here we were loaded again with 65ml metal, but this time it was loaded for us. We then headed back to Tora to unload. This time James unloaded the trailer then drove back up the hill and unhooked the trailer and went back down, truck only, to unload the bin to ensure we didn’t get stuck again.

The reason we are taking the metal to Tora is because they are putting in a culvert. This is a large pipe that runs under the road to let the water flow and prevent flooding. The metal we are laying is covering the culvert – a very important part of keeping our roads safe and usable for motorists. It may sound simple but it’s a big job that includes lots of different types of workers including a traffic management team that needs to ensure the road is clear for the truck, as it is a very narrow dirt road that can only allow vehicles travelling in one direction at a time.

We head back to Featherston to load up again and take one last load to Tora. From there we then head to Ahiaruhe River, Carterton. Here James jumps on the loader and fills up both bins, truck and trailer with river run (stones of all shapes and sizes) that we take back to Masterton and unload at the Croskery yard to be processed. That means the stones will be broken down to rough rubble to be used for future jobs.

It is about 5.30pm when we fuel up the truck and park up, it’s now knock off time. James completes his logbook and paperwork for the day. It was a great day learning about what James does in his Volvo and what Croskery Contracting is all about. Not only does James have a cool job driving trucks AND machinery, but he gets to see some hidden gems and amazing scenery in and around the Wairarapa region!

Safety first

We spend a day at the Compliance and Safety Centre with Senior Constable Ian Deane and the team at Ohakea.

Keeping our trucks and drivers safe is a very important part of our job, says Senior Constable Ian Deane. Ian used to drive trucks but decided in 1997 to join the New Zealand Police Force and has been attached to the Commercial Vehicle Inspection team for the last 14 years. He joined to help people, and enjoys the flexibility of the job and the relationships he has built with truck drivers over the years. This shows as I see them go through smiling, waving, and some even stopping to chat.

One of Ian’s teammates, Constable Barry Vinten, was already at the office when I arrived and the “All Trucks Stop“ sign was on letting truck drivers know to pull in on their way past for a quick weigh check to ensure they are travelling safe and within the requirements of the law.

If all is well, it is a very fast process where they drive up to the red light by the office where the scales are and drive over. The weight is logged on the computer inside so the constables can check details. If everything looks good then the driver gets a thumbs up, the light turns green, and the driver carries on with his day.

If there is an issue, the driver is asked to pull over and the constable will look further into the matter and if needed fill out a commercial vehicle inspection report.

Senior Constable Deane turns up with cookies and milk! We have a cuppa and talk about some of the things they do.

Weighing the trucks is important as there are limits to how much they can carry safely. Without going into too much detail, they have a list of different axle sets and lengths of vehicles that determine how much each vehicle can carry. For example: an 8 axle truck could carry 46 tonne gross weight, or a 9 axle truck could carry 50 tonne gross weight (with a permit it could carry up to 58 tonne).

But there is more to a Commercial Vehicle Safety inspector than just weighing the trucks. They also check for vehicle defects, things that may be broken or need replacing. The safety of the vehicle can include things like tyres, lights and suspension. Then there is vehicle fitness, they check to see that they are up to date with registration and road user fees and that it has a current COF (certificate of fitness) – this is a safety check done every six months to ensure everything on the truck is working properly. Dangerous goods are another thing that may need checking. Making sure the load is secured/loaded properly. And logbooks, these are a documentation of the hours a driver works with compulsory break and stop times to ensure they get rest and don’t work too long and get too tired. A truck driver can legally drive up to 70 hours in one week. That’s a lot of time trucking! They can work no more than 14 hours in one day including two half hour breaks where they can eat a meal, stretch their legs and have a breather. They must then have at least a 10 hour rest/sleep period. Once 70 hours is worked, they are required to have a minimum of 24 hours off work.

Truck drivers have huge responsibilities, and it is the duty of our Commercial Vehicle Inspection Officers to ensure they are doing their job safely, securely and legally. They are also there to help. Because they are very knowledgeable in their area of expertise drivers, truck owners/operators etc can call on them to answer any questions or enquiries regarding the legal aspects of their work.

There are around 12 Compliance and Safety Centres around New Zealand, and multiple more weigh pits where the officers use portable scales. All weigh bridges are calibrated 12 monthly. This means they are carefully assessed, set and/or adjusted. This is to make sure they are accurate and give correct readings.

Located across from the weigh bridge office are the Highway Patrol (Road Police) and administration offices. Today I saw two of these police officers called away because a truck had veered off the road. Their job is to assess the scene/ area and see what factors may have contributed to this happening and write up a report.

If It's broken we fix

No two days are the same for apprentice mechanic Natarsha Smith, who is working hard to become a specialist in heavy diesel machinery.

Natarsha works as an apprentice heavy diesel mechanic at Hyster NZ, which provides a range of fork- lifts and other handling solutions to business.

“We’ve got about 20 machines at this site with forklifts ranging from two and a half tonne right up to twenty-five tonne,” she explains.

“We fix anything on the machines that can break - so anything from the front mast to the hydraulics and the electrical and mechanical side. Whatever’s broken, we fix it – you never know what you’re going to get!”

With a day so varied, it’s no surprise that Natarsha’s favourite part of the job is problem-solving. “When you’re not sure what’s wrong and you figure it out, that’s the best.”

Study study study Natarsha’s been working at Hyster NZ in Mount Maunganui for two and a half years and is well on her way through her MITO New Zealand Certificate in Heavy Automotive Engineering. The course is designed for people interested in servicing and repairing electric and non- electric forklifts and other machinery used for moving and storing materials, goods and products.

“There was a job in Tauranga for materials handling and I thought that sounded pretty cool, so I applied and here I am! I’m really grateful it worked out the way it did. It feels like one of those things in life that’s meant to happen.”

Not just for boys

Natarsha says that despite lots of people thinking the heavy diesel industry is just for boys, it’s not true.

“The opinions of having girls doing this kind of work is improving greatly and I get really positive feedback. Especially in heavy diesel, people think it’s going to be hard work and a lot of heavy lifting, but if something weighs too much, there’s always another machine that you can use to lift it,” she says.

“I would definitely recommend this industry to anyone. It’s a lot of fun!”